Application Description

Case erecting and sealing

The powerful Jowat Toptherm® polyolefin hot melts impress with a high yield and clean processing, reducing maintenance costs and downtimes in packaging processes. Whether tray assembly, folding box sealing or wrap-arounds – the state of the art adhesive formulations with a low impact on resources keep processing costs low. The latest trends in the industry, such as shelf-ready packaging, provide significant benefits at the point of sale for retailers and consumers. Due to the attractive secondary packaging, the articles can be put directly onto the shelves. Special tray shapes with removal cut-outs provide a convenient and safe way of taking the article out of the secondary packaging. The 180° flaps on these cut-outs, however, represent a challenge for the bonding process due to the high restoring forces. To meet the requirements of this application, Jowat has developed special powerful adhesives with superior processing characteristics and high initial strength.

Jowat Toptherm® products provide the high heat resistance required for the sealing of cardboard boxes. This characteristic, however, is not only needed for hot filling. Adhesives with a high heat resistance are also essential for packaging that is exposed to high temperatures during transport. In addition, these adhesives are characterized by a good cut-off at the nozzle, excellent feed performance, and high process stability. For deep-freeze packaging, Jowat also provides special adhesives with a good flexibility at very low temperatures, excellent adhesion and high resistance to humidity and mechanical stress. This combination ensures a permanent bond.

z Folding boxes

Another major concern in the packaging industry is the risk of harmful substances migrating from the packaging material into the food. Folding boxes for food packaging are manufactured more often from recycled paper, which requires an additional barrier to protect the goods against a potential migration of varnish or print ink components. The barrier function is provided by films, or by dispersion or extrusion coatings that are applied onto the interior side of the folding box. In general, sealing folding boxes used for primary packaging is a very demanding application, due to the difficulty to assess the surface properties of the material. Jowat adhesives developed for closing primary packaging made of recycled and virgin fiber paper provide excellent results on the most different barrier coatings. These adhesive are characterized by a good cohesion at unfavorable counter pressure, plus superior adhesion to surfaces with finishing, film lamination or varnish coatings. Meeting highest requirements, these adhesives also impress in applications with sensitive products due to the excellent resistance to essential oils, such as the bergamot oil in tea.

Product Information

- Bio based hot melt

- EVA hot melt

- PO hot melt

Bio based hot melt

| Viscosity [mPas] / Temperature [°C] | Setting time [s] / Temperature [°C] | Characteristics |

Download technical data sheet (PDF) | |

|---|---|---|---|---|

| Jowatherm® GROW 853.40 | 1375 ± 375 / 120 | short | Low application temperature hot melt adhesive that is fast setting with good color and heat stability in the melt. Contains 43% USDA certified biobased content. | de us |

| Jowatherm® GROW 853.45 | 1450 ± 350 / 160 | short | Low viscosity hot melt adhesive that is fast setting with good color and heat stability in the melt. Contains 47% USDA certified biobased content. | de us |

EVA hot melt

PO hot melt

| Viscosity [mPas] / Temperature [°C] | Setting time [s] / Temperature [°C] | Characteristics |

Download technical data sheet (PDF) | |

|---|---|---|---|---|

| Jowat-Toptherm® 256.00 | 1460 ± 320 / 160 | short | Hot melt adhesive with short setting time, extremely colourfast and excellent oxidation resistance. Excellent adhesion to difficult surfaces, good flexibility at low temperatures, minimal odour. | de en fr |

| Jowat-Toptherm® 256.40 | 1050 ± 250 / 160 | 1 ± 0,5 | Hot melt with short setting time, extremely colorfast and excellent oxidation resistance. Excellent adhesion to difficult surfaces, superior flexibility at low temperatures, and good resistance of the bond to high temperatures, minimal odor. The raw materials used are approved for the packaging of food and beverages according to FDA guidelines 175.105 | es us |

| Jowat-Toptherm® 256.95 | 0.5 - 1 min. | Low application temperature hot melt with short setting time, extremely colorfast and excellent oxidation resistance. Excellent adhesion to difficult surfaces, superior flexibility at low temperatures, minimal odor. The raw materials used are approved for the packaging of food and beverages according to FDA guidelines 175.105 | es us | |

| Jowat-Toptherm® 850.60 | 1200 ± 300 / 160 | 1 ± 0,5 | Good resistance to oxidation and color stability in the melt, minimal odor. | es us |

| Jowat-Toptherm® 850.55 | 1300 ± 250 / 170 | 2-3 | Low viscosity hot melt with high hot tack, long open time, excellent color and heat resistance. Excellent mileage due to low density. Good adhesion to difficult and coated substrates. Very good adhesion for bonds exposed to high storage temperatures. The raw materials used are approved for the packaging of food and beverages according to FDA guidelines 175.105 for food packaging. | es us |

| Jowat-Toptherm® 851.99 | 1900 ± 500 / 99 | 0,7 ± 0,2 / 140 | Good adhesion. Excellent adhesive string cut-off. Low processing temperatures possible. Excellent resistance to oxidation and colour stability in the melt. A declaration concerning the food contact status of the product is available upon request. For processing with classic tank applicators or tankless melters. | de en fr |

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are necessary. For the specifications as well as further information, please refer to the latest technical data sheets.

News & Articles

Jowat has announced that its recently released GROW series of sustainable packaging adhesive has earned the USDA Certified Biobased Product label. The…

Hot melt adhesives are a small but essential component of modern packaging. An intense debate about the sustainability of packaging has not left…

High energy efficiency, very clean processing and a high content of bio-based raw materials: Jowatherm® GROW packaging adhesives provide consistent…

With its brand new products from the Jowatherm® GROW series, the adhesives expert from Detmold will be marking a milestone in the development of…

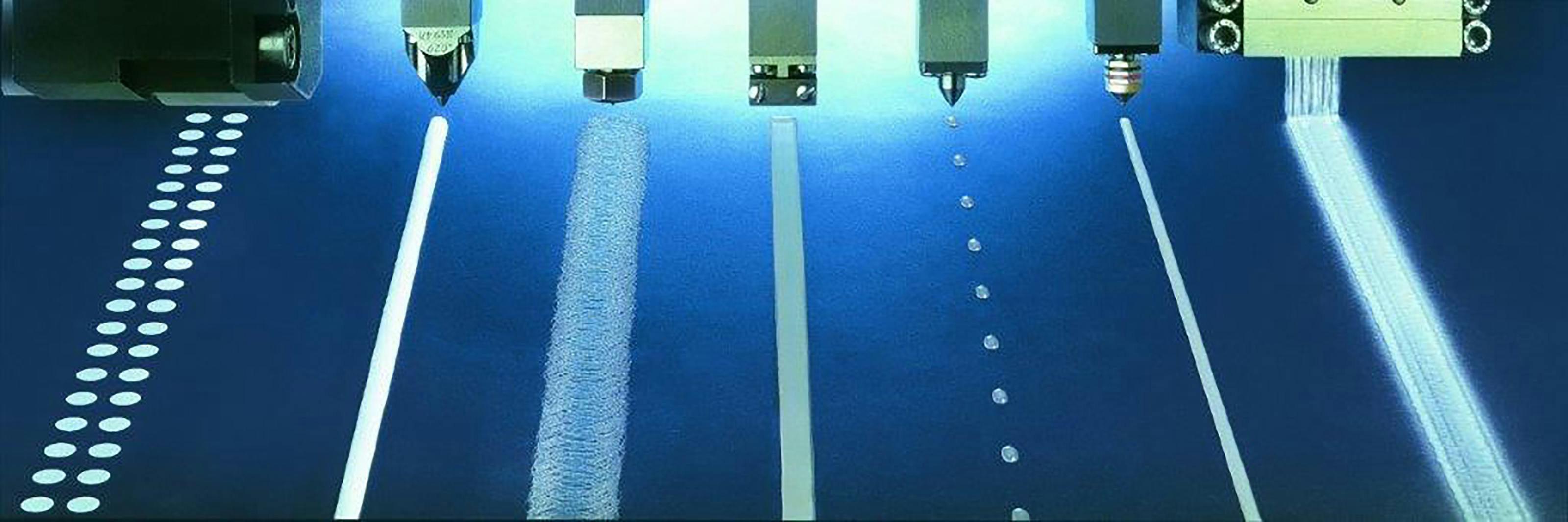

Jowat Manual with Tips and How To Guide for cleaning problems and helpful tips for adhesive changes