Description

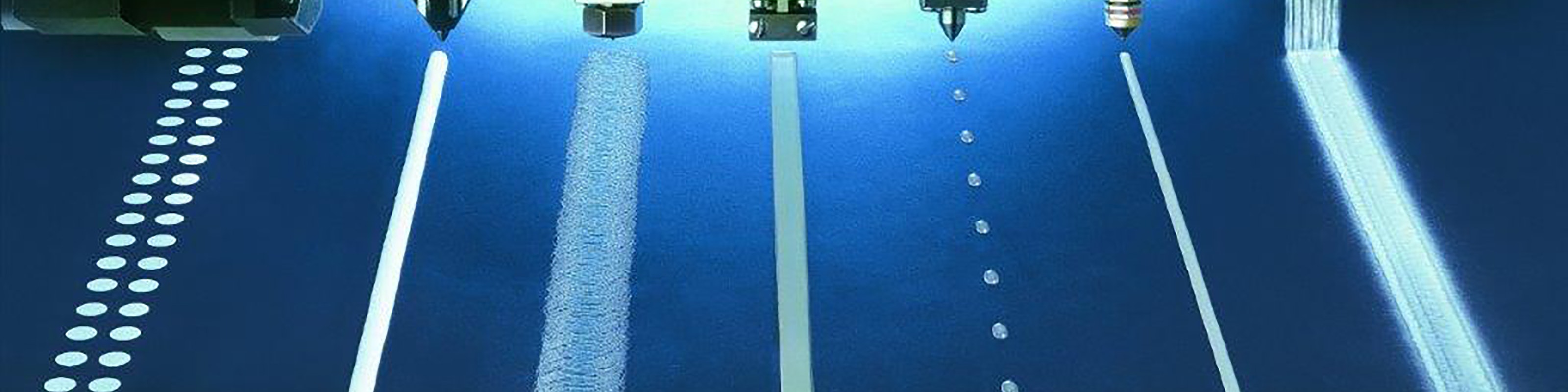

A fully functional slot nozzle application system and reservoir unit are of major importance for a smooth and reproducible adhesive application. The cleaning effort varies depending on the application system and unit, and depends largely on the type of adhesive used.

It is recommended that the application system be cleaned before any downtimes and adhesive changes. Jowat supplies a range of flushing agents and cleaners for that purpose.

Jowat® flushing agents purge the adhesive from the system and stop the chemical reaction of PUR hot melt adhesives. Before the cleaning of the application system is started, it must be ensured that the Jowat® flushing agent and the adhesive used are compatible. To prevent plugged hoses and nozzles, due to an unwanted reaction, especially in closed application systems, it must be ensured that the PUR hot melt adhesive and the Jowat® flushing agent are melted evenly.

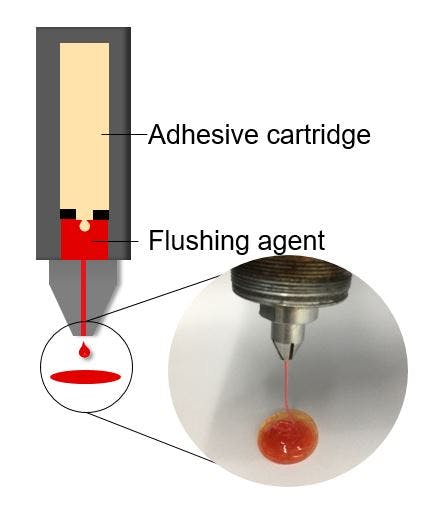

Cartridge Melter

In case of longer downtimes, flush with one half cartridge or slug of Jowat® flushing agent. Turn off the unit and allow cooling. If the processed adhesive was a PUR hot melt, it is especially important that all adhesive remnants are purged from the system. Otherwise, it could create an insoluble compound. Jowat® flushing agents contain reaction inhibitors that hinder the crosslinking of the adhesive. When starting up again, remove the container with flushing agent after heating, insert the adhesive, and make sure the adhesive extrudes all remnants of the flushing agent. Carry out the procedure until there are no more traces of red colour (only applicable for red-coloured flushing agent) in the adhesive.

Slot Nozzles and Applicator Heads

The application head, nozzle or slot nozzle may be protected overnight or on weekends with a paraffin oil or water- and acid-free mineral grease, or with a Jowat® flushing agent, so that no moisture can penetrate into the system and cause an unwanted reaction. Before start-up, thoroughly clean the nozzles from the outside (during the heating phase) and completely purge all flushing agent remnants from the system with PUR hot melt adhesive.

Changing from EVA to PO Hot Melt

Changing between hot melt adhesives based on EVA and PO can lead to an unwanted cleaning effect. Due to the different properties of the products, charred adhesive residues are detached from the reservoir wall. Those residues are then spread through the entire application system and can cause flawed bonding in the worst case. To prevent this from happening, the application system (tank, nozzles, hoses, etc.) should be flushed at low temperature and pressure with either the new adhesive itself or with Jowat® flushing agent 931.00 or 931.10 depending on the viscosity of the adhesive to be purged. In addition, the filters should be cleaned and, if necessary, replaced. Furthermore, it is also necessary to thoroughly flush the drain valve. The flushing and cleaning procedure should be repeated several times. It is recommended to clean the system again after several days or weeks. Residues can also be filtered out by installing inline filters in front of every application nozzle.

Filter screens should be checked more often at first and replaced if necessary.

Chemical Cleaning of Metal Parts

To remove stubborn soiling, e.g. charred or cured hot melt adhesive, it is recommended to use Jowat® cleaner 402.38, which will cause cured adhesive to swell and become loose.

The cleaner Jowat® 930.60 detaches charred and cured adhesive from tools, nozzles, filters, and other small parts made of metal. The disassembled metal parts may be cleaned in a heated bath at approx. 180 °C (e.g. in a commercially available deep fryer). Depending on the degree of soiling, the cleaning procedure may take about 60 to 120 minutes. The temperature of the bath must not exceed 190 °C. Remove parts from the bath, allow for cooling, rinse with water, and dry. Please also observe all recommendations of the equipment manufacturer.

Seals and other plastic parts may be dissolved and may need to be replaced!

Product information

-

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.

Safety Remarks

PUR hot melt adhesives contain isocyanate groups as reactive component. Isocyanate vapours may be released at higher adhesive temperatures. Vapours that may form are to be extracted via suitable ventilation and extraction systems. For more information concerning safety, handling, transport, and disposal, please refer to the corresponding Safety Data Sheet (available upon request). The information on this manual is based on test results from our laboratories as well as on reported experience gained in the field by our customers.

It can, however, not cover all parameters for each specific application and is therefore not binding upon Jowat, nor should it be relied upon in lieu of your own required testing. The information given in this leaflet does not represent a performance guarantee. Unless otherwise agreed with our customers, the values stated in the section “Specification” shall be regarded as the product properties finally agreed. No liability may be derived from the information contained herein nor from the information provided by our free technical advisory service.