Pollutant-/Emission-reduced Adhesives

For years, healthy living has increasingly come into focus among end consumers when it comes to house construction, interior design and furnishing. The long-term consequences that plasticizers, formaldehyde and other ingredients can leave behind are well known – accordingly, choosing the right adhesive makes a major contribution to the safety of users and end users.

Pollutant-reduced adhesives: from Jowat Green Adhesives

Sustainability is diverse. It is not always just a matter of conserving resources. Responsibility for users and end users is also part of a conscious, "green" bonding process. Therefore, low-emission adhesives are an important part of the Jowat Green Adhesive portfolio.

Emission reduced (ER) adhesives with very low emissions of formaldehyde, plasticizers and other ingredients support manufacturers in the production and bonding of low-emission products. For a contribution to environmental and customer protection.

Low VOC and FOG Adhesives

In addition to the optimum bonding of a wide variety of materials, modern adhesive technology is also ensuring more lightweight automobiles with better energy efficiency and thus lower pollutant emissions. In addition, "Low VOC and FOG adhesives" from Jowat with low VOC and FOG values contribute significantly to improving the climate in the vehicle interior.

New high-quality materials, resistant surfaces and end-customer-friendly individualization options are increasing the importance of material quality and processing in automotive interiors. Of corresponding importance are outgassing of volatile organic compounds (VOC) and the proportion of condensable substances (FOG) from materials. The quality of the air in the vehicle interior is relevant for driving comfort and the health of passengers.

What are "Low VOC and FOG Adhesives"?

Jowat offers adhesives for interior and trunk components with a very low VOC and FOG content. In addition to water-based Jowapur® PU dispersion, these are primarily innovative reactive PUR hotmelt adhesives and label-free reactive MR PUR hotmelt adhesives from the Jowatherm-Reaktant® family. In the manufacture of our "Low VOC and FOG Adhesives," we rely on raw materials with low VOC/FOG components. Selected adhesives from the "Low VOC and FOG Adhesives" range meet the requirements of many OEMs for carbon emissions, FOG, odor and formaldehyde emissions (e.g. from VW 50180).

We will be happy to provide you with the values for current and newly developed products on request.

The advantages of "Low VOC and FOG Adhesives"

- "Low VOC and FOG Adhesives" meet automotive manufacturers' delivery requirements

- Use of raw materials with low VOC and FOG content

- The quality of the air in the vehicle interior through the use of "Low VOC and FOG Adhesives" is relevant for the health of the passengers

- High process reliability

Low Formaldehyde Jowacoll® Dispersions

What does pollutant-reduced bonding mean?

The use of plasticizers is strictly forbidden in the manufacture of toys, for example - a requirement that has not yet existed for floors, for example. Classic PVC, as used in the floor area, contains plasticizers (mainly phthalate esters) which are sometimes suspected of being mutagenic and toxic to reproduction. Classic EVA dispersions that are used in flooring production also contain small amounts of plasticizers. To be able to manufacture a product free of plasticizers, a plasticizer-free adhesive is required in addition to the appropriate materials – Jowacoll® ER 147.00 fulfills this requirement.

Formaldehyde was originally used as a preservative. Adhesive base materials such as polyvinyl alcohols and vinyl acetate monomers contain formaldehyde in small amounts for procedural reasons. Due to the crosslinking reaction, reactive D3 and D4 dispersions have a significantly higher formaldehyde content than classic PVAc dispersions. In the so-called condensation reaction, formaldehyde is split off.

Through extensive investigations, Jowat has succeeded in significantly reducing the formaldehyde content by optimizing the manufacturing process. As a result, e.g. Jowacoll® 103.10 achieves a reduction in formaldehyde emissions of up to 80%. This means that the reactive Jowacoll® D3 and D4 dispersions are below the limit values defined in various guidelines, and some products are even within the detection limit.

The advantages of low-emission adhesives

A distinction is made between emissions from the liquid adhesive and emissions from the set adhesive film. On the one hand, there is the potential stress for the processor of the liquid adhesive and, on the other hand, the stress on the user of the finished component.

- Free from plasticizers

- Free from solvents

- Very low formaldehyde release

- High green strength

- Good heat resistance

- PH-level neutral

Formaldehyde is a colourless substance with a strong odour, which is gaseous at room temperature. In addition to its use and presence in different products, formaldehyde is also present in nature. Formaldehyde can be detected e.g. in the blood of mammals, in apples, grapes, and in wood. For instance, a kilogram (about two pounds) of apples has a formaldehyde content of up to 22 mg, and fresh fish up to 100 mg/kg. One kilogram of liquid Jowacoll® 103.10 has a formaldehyde content of approx. 49 mg.

If processed incorrectly, formaldehyde can cause allergies as well as irritation of the skin, eyes, and respiratory tract. High concentrations of formaldehyde are probably carcinogenic. For further information, please refer to our Safety Data Sheets. (upon request).

There are two types of emissions: from the liquid adhesive and from the cured adhesive film. Processors of the liquid adhesive are exposed to the former, and users of the end product are exposed to the latter.

The decisive limit values for the processor are the so-called Occupational Exposure Limits (OEL). These limits are measured directly at the workplace. Using appropriate measurement methods, it is, however, also possible to determine the total content of harmful ingredients like formaldehyde in the product itself.

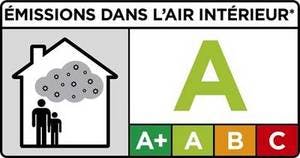

There are a number of different classification methods available for evaluating the emissions from a finished part or from a product, i.e. the emissions from the cured glue film. The French VOC regulation with its rating from A+ (very low emissions) to C (highest permissible emissions level) is a very widely used classification system.

Currently established measurement procedures determine the total amount of emissions (TVOC) as well as the emissions of ten individual substances, including formaldehyde.

Since 2012, new building products, furnishing and decoration products introduced on the French market must be classified and labelled according to their emissions. The permissible limits are based on the total VOC emissions (TVOC) as well as on the evaluation of 10 individual substances, including formaldehyde (values in micrograms per m³). Jowacoll® ER 147.00, Jowacoll® 103.10 and 103.30 meet the requirements for a A+ classification.

Food Safety

Food safety plays an major role in packaging processes. About every second packaging manufactured around the globe comes into contact with food. Compliance with food contact regulations also depends on the adhesive. Jowat provides optimum solutions consisting of tailor-made hot melt adhesives and a competent advisory service to meet the high requirements.

Since the enterprise’s early years, food safety has always been a key priority in the development of Jowat adhesives. From choosing raw materials, to meeting regulatory guidelines and supporting customers in matters related to food contact regulations. Many hot melt adhesives from the Jowat-Toptherm® and Jowatherm® series are approved for food packaging according to strict legal requirements. To support processors in their compliance effort, we also provide results from MOSH/MOAH tests and NIAS analyses in which the adhesive has been tested for non-intentionally added substances.

Technical Data

- Low Formaldehyde Dispersions

- Low VOC and FOG Adhesives

- MOSH/MOAH-free

Low Formaldehyde Dispersions

| Base | Application | Characteristics | Viscosity [mPas] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|

| Jowacoll® 103.10 | PVAc Dispersion | For all bonding purposes requiring increased resistance to wet environments, e.g. for doors, windows and furniture in high-humidity areas. General-purpose glue for soft and hardwood bonding, as well as for particleboard and other wood-based substrates, also for laying parquett and laminate (tongue-and-groove) flooring and for veneering purposes. | General D3 glue with high heat resistance. | 11000 ± 2000 / 20 | de en fr |

| Jowacoll® 103.30 | PVAc Dispersion | For all bonding purposes requiring increased resistance to wet environments, e.g. for doors, windows and furniture in high.humidity areas. General-purpose glue for soft and hardwood bonding, as well as for particleboard and other wood-based substrates. For high frequency bonding, also for laying parquet and laminate (tongue-and-groove) flooring and for veneering purposes. Flat lamination of wood-based substrates with finish foils, pressure laminates in cold and warm pressing procedures, and HF methods. Also for paper doubling. | PVAc dispersion adhesive with very high initial strength and heat resistance. | 12500 ± 2500 / 20 | de en fr |

| Jowacoll® ER 147.00 | Foil Adhesive | Dispersion of vinyl acetate copolymer for laminating PVC foils and decor paper foils to particleboard and hardboard as well as to plywood, on roller laminators and wrapping machines. | Good mechanical processing characteristics, fast setting, good heat resistance | 10000 / RT | de en fr |

Low VOC and FOG Adhesives

| Base | Application | Characteristics | Viscosity [mPas] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|

| Jowapur® 158.97 | PU Dispersion | Is used for bonding soft PVC foam foils in vaccum deepdrawing methods. It is mainly used for the production of laminated interior parts for vehicles. | Two component laminating and deepdrawing adhesive, reactivated by heat. | 305 / 25 | de en |

| Jowatherm-Reaktant® 642.00 | PUR Hot Melt Adhesive | For laminating diverse substrates to produce interior parts for the automotive industry. | Short open time and high initial strength. After complete reaction, very high bond strength coupled with outstanding resistance to heat and very good resistance to low temperatures. | 23000 / 140 | de en |

| Jowatherm-Reaktant® MR 642.90 | Monomer-Reduced PUR Hot Melt Adhesive | For laminating diverse Substrates for the production of interior parts in the automotive industry. | Monomer-reduced PUR adhesive with short open time and high initial strength. Contains a fluorescence marker for detection. | 17000 / 140 | de en fr |

MOSH/MOAH-free

| Base | Application | Characteristics | Viscosity [mPas] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|

| Jowat-Toptherm® 256.10 | Hot Melt Adhesives | Adhesive for bonding purposes in the packaging industry, for instance for closing folding boxes, wrap-around and tray erectors. | Wide range of adhesion. Clean processing. Good flexibility at low temperatures. Extremely colourfast and excellent oxidation resistance. | 1100 / 160 | de en fr |

| Jowat-Toptherm® 851.99 | PO Hot Melt Adhesive | For bonding purposes in packaging processes, e.g. for cartons, trays, and folding boxes. | Good adhesion. Excellent adhesive string cut-off. Low processing temperatures possible. Excellent resistance to oxidation and colour stability in the melt. A declaration concerning the food contact status of the product is available upon request. For processing with classic tank applicators or tankless melters. | 1900 ± 500 / 99 | de en fr |

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.