Application Description

Adhesives play a major role in the manufacture and assembly of the different parts for car interiors. Whether tried and proven for many years or tailored to specific applications, Jowat supplies the suitable adhesive solution for all current requirements and process parameters in all established bonding methods.

A particularly demanding application is the lamination of instrument panels, side and door panelling, and centre consoles with a wide variety of different decor materials. Jowat provides a broad spectrum of suitable bonding solutions with highest heat resistances, which reaches far beyond the standard applications, such as press laminating and vacuum deep-drawing.

PO hot melts facilitate the lamination of polypropylene form parts in IMG processes without pretreatment and provide a fully recyclable compound. Powerful PUR hot melts are ideal in all laminating procedures for the entire vehicle interior. And for the top league of lamination, for instance the real leather lamination of instrument panels and door panelling with visible seams, Jowat supplies PU dispersions which have been optimised specially for these mostly manual assemblies.

More frequently thin and porous textiles are used to cover A-B-C columns, parcel shelves or ceilings. These applications are exposed to direct sunlight and are therefore laminated with highly UV-stable PU dispersions. Even after many years of exposure, the bondline will remain invisible due to the excellent oxidation resistance and colour stability of these adhesives.

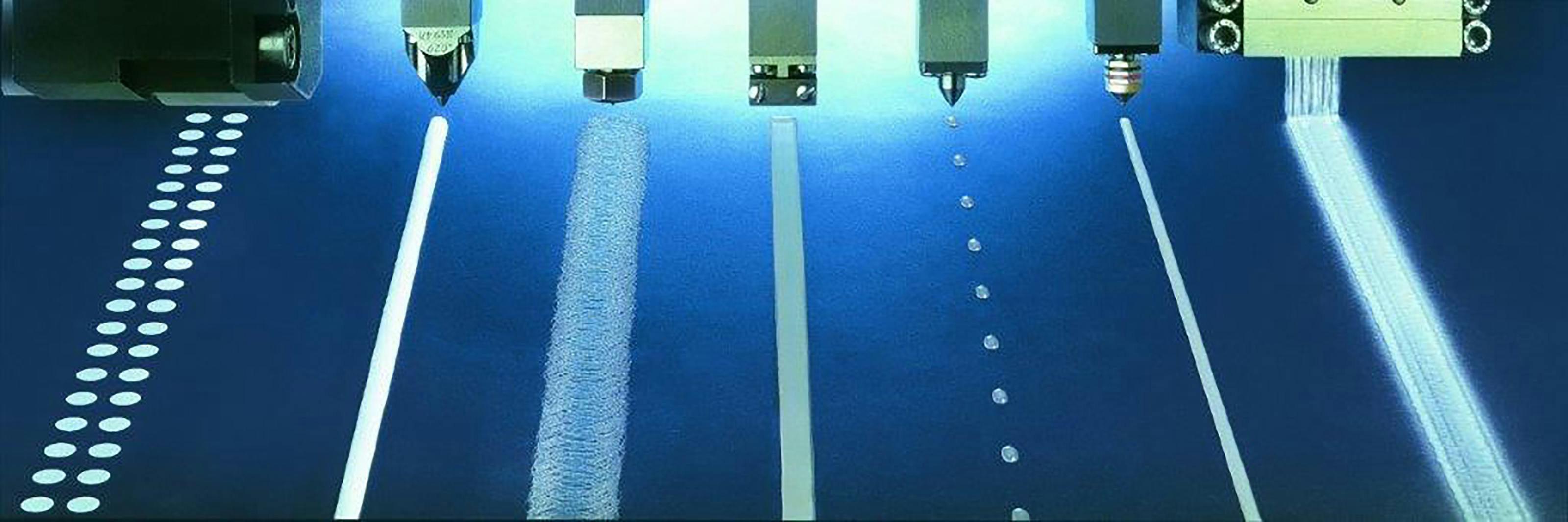

Jowat adhesives for car interiors support the efficiency of modern manufacturing processes with regard to all lamination methods, including VACFLOW – short process cycles, low energy consumption, and clean processing – as well as the specific requirements of the different parts. Our product range provides for each application suitable products with a broad spectrum of different initial strengths and activation temperatures, edgefolding capability, heat and UV resistances, as well as precoatings with good storage stability for products supplied on reels.

Product characteristics of Jowatherm-Reaktant® PUR hot melt Adhesives:

- High resistance to heat and fluids

- Wide range of adhesion and high strength

- High resistance to plasticizers

- Low processing temperatures

- Low reactivation temperatures

- Meets established tests and inspections from the automotive industry

Product characteristics of Jowat-Toptherm® PO hot melt adhesives:

- Good adhesion to nonpolar substrates, e.g. polypropylene, NF-PP

- External precoating possible

- Easy and user-friendly processing

- Good adhesion to TPO foils

Product characteristics of Jowapur® PU dispersion adhesives:

- Easy processing

- Manual processes are possible

- Can be repositioned (e.g. sewn covers)

- Good spraying characteristics

- Short pressing times inside the press

- No cooling inside the press necessary

- Low VOC and fogging values

| Upper Door Trims | ||

| Materials (examples): | Carrier substrate: ABS, PP, PC/ABS | |

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Armrest | ||

| Materials (examples): | Carrier substrate: ABS, PC, PC/ABS | |

| Foams: different foams | ||

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives, Jowatherm-Reaktant® POR hot melts | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Map Bag | ||

| Materials (examples): | Carrier substrate: AABS, PP, PC/ABS, PC | |

| Foams: spacer fabrics, different foams | ||

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives, Jowatherm-Reaktant® POR hot melts, Jowat-Toptherm® PO hot melts | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 | ||

| Jowat-Toptherm® 238.20 |

| Center Console | ||

| Materials (examples): | Carrier substrate: PP, ABS, PC/ABS | |

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives, Jowatherm-Reaktant® POR hot melts | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Seats | ||

| Materials (examples): | Carrier substrate: PU foams | |

| Decor material: genuine leather, PVC foil, TPO foam foils, textiles | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Backrest | ||

| Materials (examples): | Carrier substrate: NFPP, wood fiberboard/textile composite | |

| Decor material: PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives, Jowatherm-Reaktant® POR hot melts, Jowat-Toptherm® PO hot melts | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Door Panels | ||

| Materials (examples): | Carrier substrate: ABS, PP, PC/ABS, PC | |

| Foams: spacer fabric, different foams | ||

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives, Jowatherm-Reaktant® POR hot melts, Jowat-Toptherm® PO hot melts | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Pillar Trim | ||

| Materials (examples): | Carrier substrate: ABS, PP, PC/ABS | |

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Instrument Panel | ||

| Materials (examples): | Carrier substrate: ABS, PP, PC/ABS, PPGF20 | |

| Foams: spacer fabric, different foams | ||

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowatherm-Reaktant® 630.80 | ||

| Jowapur® 158.97 |

| Upper Door Trims | ||

| Materials (examples): | Carrier substrate: ABS, PP, PC/ABS | |

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Armrest | ||

| Materials (examples): | Carrier substrate: ABS, PC, PC/ABS | |

| Foams: different foams | ||

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives, Jowatherm-Reaktant® POR hot melts | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Map Bag | ||

| Materials (examples): | Carrier substrate: AABS, PP, PC/ABS, PC | |

| Foams: spacer fabrics, different foams | ||

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives, Jowatherm-Reaktant® POR hot melts, Jowat-Toptherm® PO hot melts | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 | ||

| Jowat-Toptherm® 238.20 |

| Center Console | ||

| Materials (examples): | Carrier substrate: PP, ABS, PC/ABS | |

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives, Jowatherm-Reaktant® POR hot melts | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Seats | ||

| Materials (examples): | Carrier substrate: PU foams | |

| Decor material: genuine leather, PVC foil, TPO foam foils, textiles | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Backrest | ||

| Materials (examples): | Carrier substrate: NFPP, wood fiberboard/textile composite | |

| Decor material: PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives, Jowatherm-Reaktant® POR hot melts, Jowat-Toptherm® PO hot melts | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Door Panels | ||

| Materials (examples): | Carrier substrate: ABS, PP, PC/ABS, PC | |

| Foams: spacer fabric, different foams | ||

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives, Jowatherm-Reaktant® POR hot melts, Jowat-Toptherm® PO hot melts | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Pillar Trim | ||

| Materials (examples): | Carrier substrate: ABS, PP, PC/ABS | |

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowapur® 158.97 |

| Instrument Panel | ||

| Materials (examples): | Carrier substrate: ABS, PP, PC/ABS, PPGF20 | |

| Foams: spacer fabric, different foams | ||

| Decor material: genuine leather, PVC foil, TPO foam foils | ||

| Adhesive systems (examples): | Jowatherm-Reaktant® PUR hot melts, Jowatherm-Reaktant® MR PUR hot melts, Jowapur® PU dispersion adhesives | |

| Products (examples): | Jowatherm-Reaktant® MR 642.90 | |

| Jowatherm-Reaktant® 642.00 | ||

| Jowatherm-Reaktant® 642.30 | ||

| Jowatherm-Reaktant® 613.10 | ||

| Jowatherm-Reaktant® 613.79 | ||

| Jowatherm-Reaktant® 630.80 | ||

| Jowapur® 158.97 |

Product Information

- dispersion

- hot melt adhesive

dispersion

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Application | Components / Crosslinking Agent |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|

| Jowapur® 158.97 | PU Dispersion | 305 / 25 | 20 | Is used for bonding soft PVC foam foils in vaccum deepdrawing methods. It is mainly used for the production of laminated interior parts for vehicles. | 197.65 | de en |

hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Application | Components / Crosslinking Agent |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|

| Jowatherm-Reaktant® 613.18 | PUR Hot Melt Adhesive | 20000 /140 | 130 - 160 | Laminating adhesive for manufacturing interior panellings in automobiles, for instance door panelling and dashboards. | de en fr | |

| Jowatherm-Reaktant® 613.79 | PUR Hot Melt Adhesive | 35000 / 140 | 130 - 150 | For lamination of sandwich elements with carpet velour, and for other laminating operations in the automotive industry, for instance hat racks, trunk floors, interior door panelling and interior fittings. | ||

| Jowatherm-Reaktant® 630.80 | PUR Hot Melt Adhesive | 8000 / 140 | 110 - 140 | interior car panelling for instance hat racks, roof liners, door panelling etc.; compound materials | de en fr | |

| Jowatherm-Reaktant® 642.00 | PUR Hot Melt Adhesive | 23000 / 140 | 110 - 150 | For laminating diverse substrates to produce interior parts for the automotive industry. | de en | |

| Jowat-Toptherm® 238.20 | PO Hot Melt Adhesive | 20000 ± 2000 / 200 | 180 - 200 | For flat lamination, for instance of substrates based on PP (NF-PP) in the automotive industry, also edgefolding operations. Also for precoating of reel material. | de en fr | |

| Jowat-Toptherm® 238.80 | PO Hot Melt Adhesive | 25000 ± 5000 / 200 | 180 - 200 | For flat lamination and assembly operations (for instance edging processes, clip bonding). | de en fr | |

| Jowat-Toptherm® 221.00 | PO Hot Melt Adhesive | 23200 ± 2200 / 200 | For bonding edgebands for instance of HPL/CPL, polyester, resinated paper, solid wood and veneer. | de en fr | ||

| Jowatherm-Reaktant® MR 642.90 | Monomer-Reduced PUR Hot Melt Adhesive | 17000 / 140 | 110 - 150 | For laminating diverse Substrates for the production of interior parts in the automotive industry. | de en fr | |

| Jowatherm-Reaktant® 642.30 | PUR Hot Melt Adhesive | 20000 ± 5000 / 140 | 110 - 130 (roller application) 130 - 150 (spraying) | For the manufacture of composite materials in the automotive industry. | de en |

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.

News & Articles

Jowat Manual with Tips and How To Guide for cleaning problems and helpful tips for adhesive changes

PUR hot melts with a reduced monomer content and which are therefore non-hazardous are in high demand in the automotive industry as well. A new…

Modern manufacturing processes in the automotive industry would be inconceivable without bonding technology. About 15 kg of adhesive per car are used…

Jowat now supplies a new high-performance dispersion for the lamination of interior car parts: The special formulation of the dispersion based on…

Detmold, August 8, 2016 – Jowat has introduced a powerful all-round adhesive for all laminating processes of vehicle interiors. The new…