Application Description

Modern compound elements or sandwich assemblies have only become possible thanks to the use of modern high-performance adhesives. Today, large-surface compound elements have become necessary elements for many industrial areas. They are used for special vehicles, interior shipbuilding, construction elements, but also in furniture manufacture and many other applications. The material mix, resulting from the specific demands on the compound element, requires special adhesives, which are often tailored for the process, especially with regard to their resistance to heat, moisture or cold, or with regard to the fire resistance properties.

Product Information

- 1-component

- 2-component

- hot melt adhesive

1-component

2-component

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Open Time [min] / Temperature [°C] | Application | Certificate |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowapur® 688.30 + 688.99 | 2-Component PUR Adhesive | 6000 / 20 | > 10 | 20 - 30 / 20 | Two-component adhesive for small and large industrial applications and small shops. Bonding and fixing of various types of wood, plywood, particleboard, mineral fibreboard panels, metals like iron, galvanized iron plate, aluminium etc, fibre-reinforced polyester, foamed plastics like expanded polystyrene, PVC and plastic honeycombs. | de en fr | |

| Jowapur® 688.80 + 688.99 | 2-Component PUR Adhesive | 6000 / 20 | > 10 | 60 - 80 / 20 | Two-component adhesive for small and large industrial applications and small shops. Bonding and fixing of various types of wood, plywood, particleboard, mineral fibreboard panels, metals like iron, galvanized iron plate, aluminium etc, fibre-reinforced polyester, foamed plastics like expanded polystyrene, PVC and plastic honeycombs. | ||

| Jowat® 690.00 | 2-Component SE Polymer | 50000 | 20 | For flexible bonding of plastics, metals and rubber materials, also for sealing seams and as casting compound. | de en fr | ||

| Jowat® 691.45 | 2-Component SE Polymer | thixotropic / 20 | 20 | For flexible bonding of plastics, metals and rubber materials, also for sealing seams and as casting compound. | de en fr | ||

| Jowapur® 688.60 + 688.99 | 2-Component PUR Adhesive | 6000 / 20 | 10 - 50 | 40 - 60 | Two-component adhesive for small and large industrial applications and small Shops. Bonding and Fixing of various types of Wood, plywood, particleboard, Mineral fibreboard panles, metals like iron, galvanized iron plate, Aluminium etc. |

hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Open Time [min] / Temperature [°C] | Application | Certificate |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowatherm-Reaktant® 609.30 | PUR Hot Melt Adhesive | 15000 ± 3000 / 120 | 110 - 130 | 3 ± 1 / 120 | For flat lamination and the manufacture of sandwich elements, also for assembly applications in the woodworking and automotive industries. | A.1/3.18 e | de en fr |

| Jowatherm-Reaktant® 609.45 | PUR Hot Melt Adhesive | 31000 ± 11000 / 120 | 100 - 130 | 1 ± 0,2 / 120 | For flat lamination and the manufacture of sandwich elements and for wrapping wood and plastic profiles with non-transparent foils and with decor papers. | A.1/3.18 e | de en fr |

| Jowatherm-Reaktant® 609.50 | PUR Hot Melt Adhesive | 25000 ± 5000 / 120 | 120 - 140 | 1 ,5 ± 0,5 / 120 | For flat lamination and for the manufacture of sandwich elements, also for assembly operations in the wood- and automotive industries. | A.1/3.18 e | de en fr |

| Jowatherm-Reaktant® MR 609.93 | Monomer-Reduced PUR Hot Melt Adhesive | 14000 ± 4000 | 110 - 130 | 3 ± 1 | For flat lamination and for the manufacturer of Sandwich Elements, also for Assembly operations in the Wood Industry. | de en fr | |

| Jowatherm-Reaktant® 609.00 | PUR Hot Melt Adhesive | 17000 ± 5000 / 120 | 110 - 130 | 4 ± 1 / 120 | For flat lamination and for the manufacture of sandwich elements, also for assembly operations. | de en fr |

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.

News & Articles

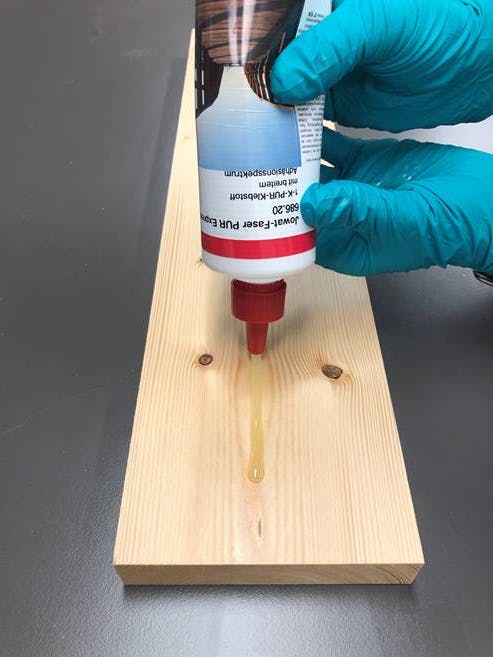

Find out everything you need to know about handling PUR Prepolymer Adhesives. All details can be found in the attached PDF brochure.

Jowat Manual with Tips and How To Guide - we help you finding the solution to your PUR cleaning problems

Further Applications

Further applications in the field of „Building Elements”

- Textile lamination (Building textiles)

- Spacers

- Assembly Bonding

- Precast concrete parts

- Window profile wrapping

- Exterior doors

- Interior doors (Flat lamination)

- Wood windows manufacture

- Parquet manufacture

- Manufacture of laminate-, vinyl- and design flooring

- Access floor manufacture

- Textile floor coverings

- Profile wrapping (skirting boards)

- Appretur

- Insulation Materials