Application Description

Open for everything

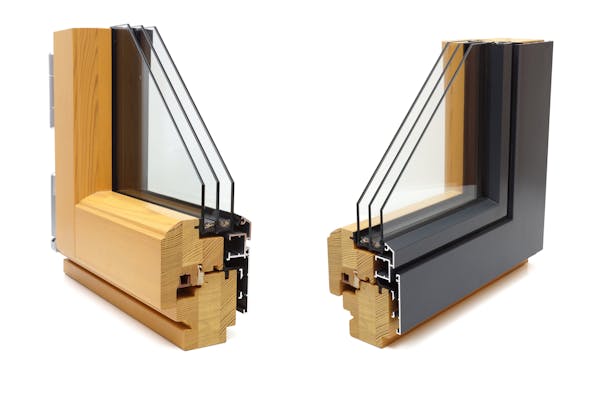

A permanent resistance of the solid wood elements is essential due to the exposure of these products to outdoor conditions. The Jowat product portfolio with powerful D4 dispersions, EPI dispersions and PUR adhesives provides processors with the opportunity to meet different requirements.

Requirements for adhesive bonding today are higher than ever before. More and more building owners attach particular importance to the impact of construction products on human health and the environment.

Demand for wood windows therefore remains unbroken. Elaborate designs, long-lasting surface coatings and the combination with other materials facilitate classic wood windows with high resistance and at the same time visual appeal.

Apart from their characteristic, natural properties, wood windows are also increasingly becoming established as an ecological alternative. Wood has excellent carbon storage properties and therefore its use contributes to a climate-friendly environment.

The Jowacoll® dispersion adhesives with durability class D4 (according to EN 204/205) currently used in the manufacture of window scantlings are characterised by high bond strength and uncomplicated processing.

For even higher requirements with regard to water and temperature resistance, Jowat supplies dispersion adhesives based on emulsion polymer isocyanate (EPI). These adhesives provide superior strength due to a high degree of crosslinking, while also being easy to process like PVAc dispersion adhesives.

The Jowat portfolio allows processors to choose the right adhesive for the individual process. With the powerful Jowacoll® dispersion adhesives, Jowat supplies a multitude of alternatives for efficient bonding. The extensive product range provides solutions for different application technologies, whether by roller, blade, nozzle or pouring.

With extensive expertise in the industry, Jowat understands the requirements for the end products and is consistently developing its portfolio further.

Product Information

- 2-component

- 1-component

2-component

| Base | Open Time [min] / Temperature [°C] | Classification acc. to EN 204 | Application |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|

| Jowacoll® 102.26 | PVAc Dispersion | 7 - 10 / 20 | D4 / WATT91 > 7 N/mm² | For all bondings requiring increased resistance to humid environments, e.g. doors, windows and furniture in high-humidity areas. | de en fr |

| Jowacoll® 102.50 | Copolymer Dispersion | 8 - 12 / 20 | D4 / WATT91 > 7 N/mm² | Copolymer dispersion for bonding hard wood species, species with high resin content, tropical wood species and wood with moisture content up to 15%. | de en fr |

1-component

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.