Application Description

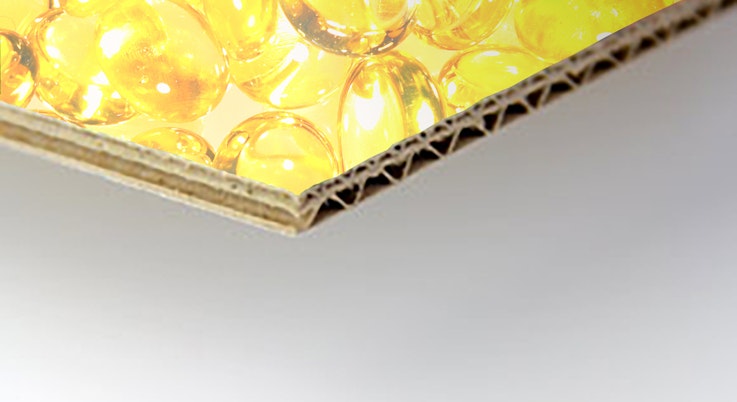

Sheet lamination of printed paper material is a widely used finishing method for many different products, for instance folders, book covers, board games, jigsaw puzzles or display packaging. Laminated cardboards made of a corrugated cardboard base and laminated with printed paper are manufactured on sheet-to-sheet laminators with a laminating section and a delivery section. In the lamination process, different materials with a high-quality pre-printed surface are bonded to a cardboard or corrugated cardboard substrate. A gluing unit applies the adhesive to the flute tips (open flute) or the top layer of the carrier substrate and aligns it with the printed top sheet. In the final step, the substrates are then bonded together. The adhesive has to meet special requirements: facilitate clean processing on roller applicators, no foaming, no odour, and excellent flatness of the compound – with maximum adhesion.

POS displays

Placed prominently in retail stores, from supermarkets to pharmacies and petrol stations, eye-catching point-of-sale displays draw the customers’ attention to special offers and product campaigns. Due to the generally limited lifecycle, they must be easy to handle while also providing enough stability for the products showcased in them. Enterprises also have to react spontaneously and fast to new market developments.

Therefore, POS displays need to be manufactured from a sustainable material which can be disposed in an environmentally sensitive way once the promotion has ended. Jowat has developed special dispersion adhesives for this purpose to join the printed papers and the carrier material (in this application, usually corrugated cardboard).

Board games

While online games have become increasingly popular among young and old alike, classic board games still hold a strong appeal to game lovers.

Board games are also manufactured by laminating a carrier substrate with a pre-printed paper. To ensure the highest quality possible in this process, Jowat has developed special Jowacoll® dispersion adhesives that withstand the high stress to which the material is exposed. Glues from the Jowacoll® series also facilitate superior results in the manufacture of folders.

Jowat has many years of experience in bonding all types of papers and cardboards – whether on highly absorbent greyboard, in the overlapping area, paper with plastic content or printed with digital printing inks. The dispersion adhesives, crosslinking agents and cleaners by Jowat are perfectly adapted to each other and meet all individual requirements: excellent adhesion, no wave structures, and optimum LayFlat properties.

Product Information

- Optimal price / Performance

- High Performance

Optimal price / Performance

High Performance

| Base | Viscosity [mPas] / Temperature [°C] | Solids [%] | Application |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|

| Jowacoll® 745.60 | Copolymer Dispersion | 2000 | 54 | Bookbinding and print processing, file/folder manufacture, paper and packaging industry | de en fr |

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.