Application description

Whether outdoor furniture, patio decking or facades and bridges: The fields of application are constantly increasing for the modified wood species which have been highly demanded for several years. The great challenges in manufacturing are met with special adhesives.

Specialists for the bonding of treated wood

Wood species which are naturally less durable undergo a chemical or thermal modification procedure to increase the moisture and heat resistance and to make the wood suitable for outdoor use. After a thermal treatment during which the wood is heated to a defined temperature and then cooled down, the water absorption speed of the wood is reduced significantly. In addition, this procedure also changes the appearance of the wood, making it darker. Alternatively, the wood may be impregnated and given water-repellent properties through a chemical modification process.

However, modified wood with a higher resistance to weathering also is more difficult to bond. Adhesives used for bonding these materials face a great challenge and have to be significantly more powerful than products used for bonding untreated wood. The substantially reduced moisture absorption and release as well as the added ingredients have a huge impact on the bonding properties of the substrate. This may lead for instance to chemical interactions with the added chemicals, which can have a detrimental effect on the bonding result. In addition, the use of water-based adhesives is usually also uneconomical. Due to the hydrophobic treatment of the wood, the water becomes trapped in the glueline and dries only slowly. This leads to much longer pressing times.

For bonding modified wood, Jowat provides special, chemically crosslinking adhesives which optimally meet the superior requirements. EPI (Emulsion Polymer Isocyanate) adhesives which are processed as two-component systems and mixed with isocyanate crosslinkers, ensure a fast setting of the adhesive even on durable wood with reduced water absorption. In addition, the chemical reaction of the crosslinking agent leads to a bond with high heat resistance. Therefore, EPI adhesives are optimally suitable for gluing hardwood, wood with a high resin content, and tropical wood species even with direct exposure to weathering. Due to the solids content of 100 percent, the setting time of one-component PUR prepolymers is not affected by the reduced water absorption of the wood. Both adhesive systems enable bonds with a moisture resistance considerably superior to the requirements for the durability class D4 of the EN 204 and reach tensile shear resistances >7 N/mm² at 80 °C in heat resistance tests according to EN 14257 (Watt 91).

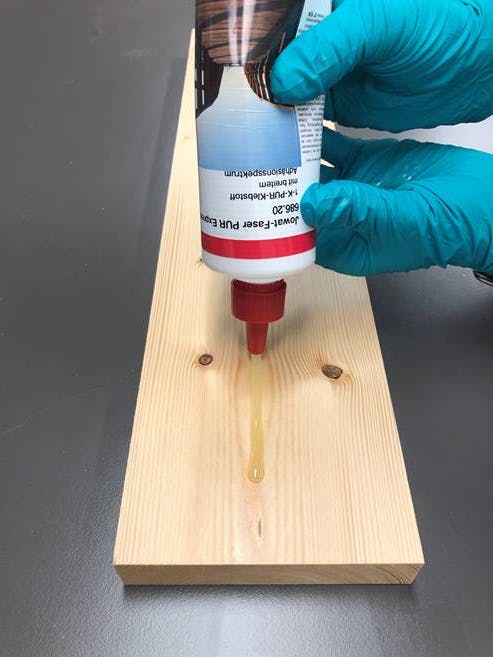

1.

1.Specimen: Accoya® scantling...

2.

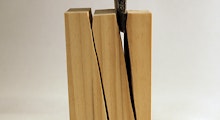

2....in the splitting process...

3.

3....after Splitting: 100 % wood failure.

Product Information

- EPI

- PUR-Prepolymer

EPI

| Base | Viscosity [mPas] / Temperature [°C] | Open Time [min] / Temperature [°C] | Application |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|

| Jowacoll® 102.50 | Copolymer Dispersion | 11000 / 20 | 8 - 12 / 20 | Copolymer dispersion for bonding hard wood species, species with high resin content, tropical wood species and wood with moisture content up to 15%. | de en fr |

PUR-Prepolymer

| Base | Viscosity [mPas] / Temperature [°C] | Open Time [min] / Temperature [°C] | Application |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|

| Jowapur® 686.60 | 1-Component PUR Prepolymer | 10500 / 20 | 45 / 20 | Manufacturing bonded load-bearing timber structures | de en fr |

| Jowapur® 687.40 | 1-Component PUR Prepolymer | 6000 / 20 | 30 - 40 / 20 | Adhesive for bonding of hard wood species, composites of HPL/CPL, bonding to galvanized iron or metals, bonding expanded polystyrene (sanded) to wood, stone and many other substrates. | de en fr |

| Jowapur® 681.10 | 1-Component PUR Prepolymer | 15500 ± 2500 / 20 | 10 / 20 | Manufacturing bonded load-bearing timber structures | de en fr |

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.

News & Articles

Find out everything you need to know about handling PUR Prepolymer Adhesives. All details can be found in the attached PDF brochure.

Elegant and with a rich tradition, the paddle wheel steamer offers guests a very unique atmosphere on Lake Constance. Rising gastronomical demands…