Descripción de la aplicación

Modernos sistemas adhesivos para superficies perfectas

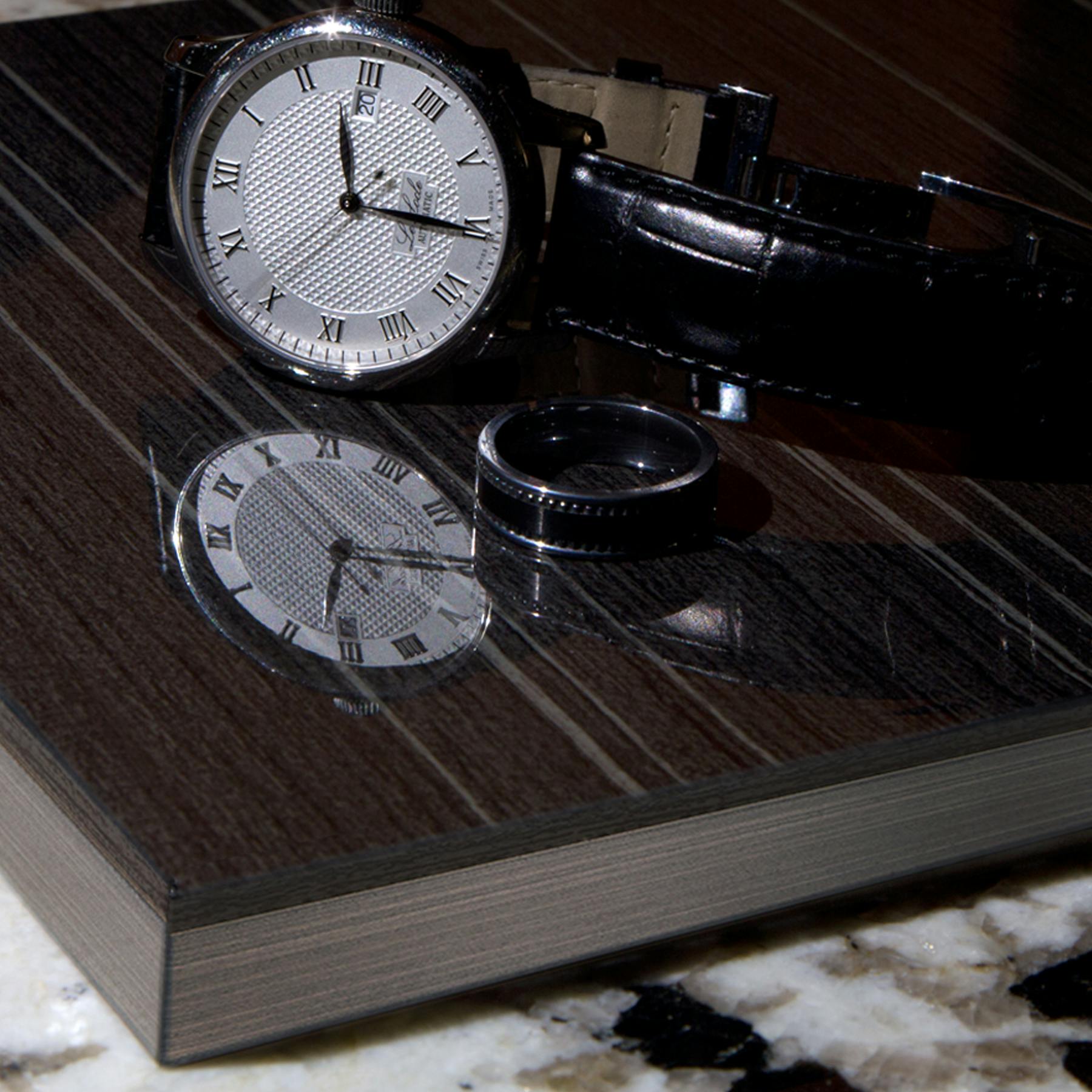

For many years, flat lamination applications have been a growth market in the wood and furniture industry with constantly increasing requirements for manufacturing processes as well as for the used adhesives.

In the manufacture of modern furniture, wood-based panels are surface-laminated with the most diverse materials. Frequently used materials are resinated decor foils, veneers, as well as thermoplastic foils, CPL and HPL. The finished panels have numerous different applications: from the kitchen and home furniture to general interior fittings and floorings, the shipbuilding and caravan industries, as well as for exhibition displays and shopfitting. Decoratively laminated panels and profiles are the current state of the art.

The mentioned materials are bonded using a variety of technologies which demand specific optimised adhesive solutions. For years, the state of technology was processing with Urea Formaldehyde (UF) adhesives. These are, however, viewed with growing reserve, due to current aspects of health and ecology. Innovative Jowat adhesive systems on dispersion or hot melt bases are the efficient alternatives. Polyurethane hot melts have been established in the market for many years and are the products of choice for applications which require a superior bonding quality.

Información del Producto

- PUR hot melt adhesive

- hot melt adhesive

- dispersion

PUR hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film | Open Time [min] / Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowatherm-Reaktant® 609.30 | PUR Hot Melt Adhesive | 15000 ± 3000 / 120 | 180 ± 60 / 120 | 3 ± 1 / 120 | 60 ± 5 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® 609.36 | PUR Hot Melt Adhesive | 13250 ± 3750 / 120 | 300 ± 60 / 120 | 5 ± 1 / 120 | 65 ± 5 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® 609.40 | PUR Hot Melt Adhesive | 7500 ± 1500 / 120 | 120 ± 60 / 120 | 2 ± 1 / 120 | 65 ± 5 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® 609.50 | PUR Hot Melt Adhesive | 25000 ± 5000 / 120 | 90 ± 30 / 120 | 1 ,5 ± 0,5 / 120 | 65 ± 5 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® MR 609.93 | Monomer-Reduced PUR Hot Melt Adhesive | 14000 ± 4000 | 180 ± 60 | 3 ± 1 | 65 ± 5 | 1,1 ± 0,1 / 20 | de en fr |

| Jowatherm-Reaktant® 609.00 | PUR Hot Melt Adhesive | 17000 ± 5000 / 120 | 240 ± 60 / 120 | 4 ± 1 / 120 | 60 ± 5 | 1,1 ± 0,1 / 20 | de en fr |

| Jowatherm-Reaktant® MR 609.90 | Monomer-Reduced PUR Hot Melt Adhesive | 30000 ± 10000 / 120 | 3 ± 1 / 120 | 65 ± 5 | de en fr |

hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film | Open Time [min] / Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowat-Toptherm® 236.50 | PO Hot Melt Adhesive | 8000 ± 2000 / 200 | 15 ± 2 / 190 / 120 | 110 ± 5 | 0,87 ± 0,02 / 20 | de en fr | |

| Jowatherm® 291.60 | EVA Hot Melt Adhesive | 5550 ± 1270 / 200 | 6 ± 2 / 180 / 120 | 80 ± 5 | 1,00 ± 0,02 / 20 | de en fr |

dispersion

| Base | Viscosity [mPas] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film | Open Time [min] / Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowacoll® 103.10 | PVAc Dispersion | 11000 ± 2000 / 20 | 6 ± 2 / RT | 1,08 ± 0,05 / 20 | de en fr | ||

| Jowacoll® 103.30 | PVAc Dispersion | 12500 ± 2500 / 20 | 9 ± 3 / RT | 1,08 ± 0,05 / 20 | de en fr | ||

| Jowacoll® 103.70 | PVAc Dispersion | 10000 / 20 | 5 - 7 / RT | 1,08 ± 0,05 / 20 | de en fr | ||

| Jowacoll® 124.00 | PVAc Glue for Flat Bonding | 9500 ± 1000 / 20 | 6 ± 1 / RT | 1,24 ± 0,05 / 20 | de en fr | ||

| Jowacoll® 124.79 | PVAc Glue | 19500 / 20 | 8 - 10 / RT | 1,24 ± 0,05 / 20 | de en fr | ||

| Jowacoll® ER 147.00 | Foil Adhesive | 10000 / RT | 0 – 3 | 1,35 ± 0,05 / RT | de en fr | ||

| Jowacoll® 148.00 | Foil Adhesive | 12000 ± 4000 / 20 | 0 – 3 | 1,35 ± 0,05 / RT | de en fr | ||

| Jowacoll® 148.20 | Foil Adhesive | 23000 / 20 | 0 – 3 | 1,35 ± 0,05 / RT | de en fr | ||

| Jowacoll® 148.70 | Foil Adhesive | 10000 / 20 | 0 - 4 | 1,25 ± 0,05 / RT | de en fr |

Los productos enumerados solo representan una selección limitada de la cartera de productos disponible. La disponibilidad del producto puede variar según la región. Los datos técnicos, las características y el campo de aplicación proporcionados en la tabla describen las diferencias entre los adhesivos individuales de la cartera de productos. Nuestro Departamento de Tecnología de Aplicación y nuestros Representantes de Ventas están disponibles para brindarle asesoramiento y ayudarlo a encontrar el mejor adhesivo para su aplicación particular.

Nota: La información de esta página se basa en los resultados de las pruebas de nuestros laboratorios, así como en la experiencia adquirida en el campo, y de ninguna manera constituye una garantía de propiedades. Debido a la amplia gama de diferentes aplicaciones, sustratos y métodos de procesamiento fuera de nuestro control, no se puede derivar ninguna responsabilidad de estas indicaciones ni de la información proporcionada por nuestro servicio gratuito de asesoramiento técnico. Las pruebas del cliente en las condiciones diarias, las pruebas de idoneidad en las condiciones normales de procesamiento y las pruebas de ajuste adecuadas para el propósito son absolutamente necesarias. Para obtener las especificaciones y más información, consulte las fichas técnicas más recientes.

Noticias y Artículos

Say hello to sand oak, concrete look and alpine white. These names refer to a small selection of numberless body colours that furniture store…

Jowat Manual with Tips and How To Guide - we help you finding the solution to your PUR cleaning problems

For many years, lacquering and decor foil lamination have been established finishing methods in the manufacture of wood-based materials for the…

The demand for environmentally compatible and harmless furnishings has constantly grown over the past years. Architects and interior fitters now have…

Like in any relationship, tensions are not desired when it comes to laminating surfaces. Tensions, i.e. mechanical stress, acting in and on the joint…

A new Jowat dispersion adhesive received the highest classification A+ from “Émissions dans l’air interieur,” currently the strictest rating system in…

otras aplicaciones

Otras aplicaciones en el campo de „Industria del mueble”

- Adhesión de cantos

- Revestimiento de perfiles

- 3D lamination

- Postforming | Worktop sealing

- Primer

- Dowelling and frame bonding

- Rack production

- Upholstery

- Assembly of pocket spring mattresses

- Manufacture of foam mattresses

- Foam lamination

- Assembly bonding (furniture/interior)

- Laminado textil (tejidos de cubierta)

- Embalaje