Descrizione

Per prodotti più attraenti nel punto vendita.

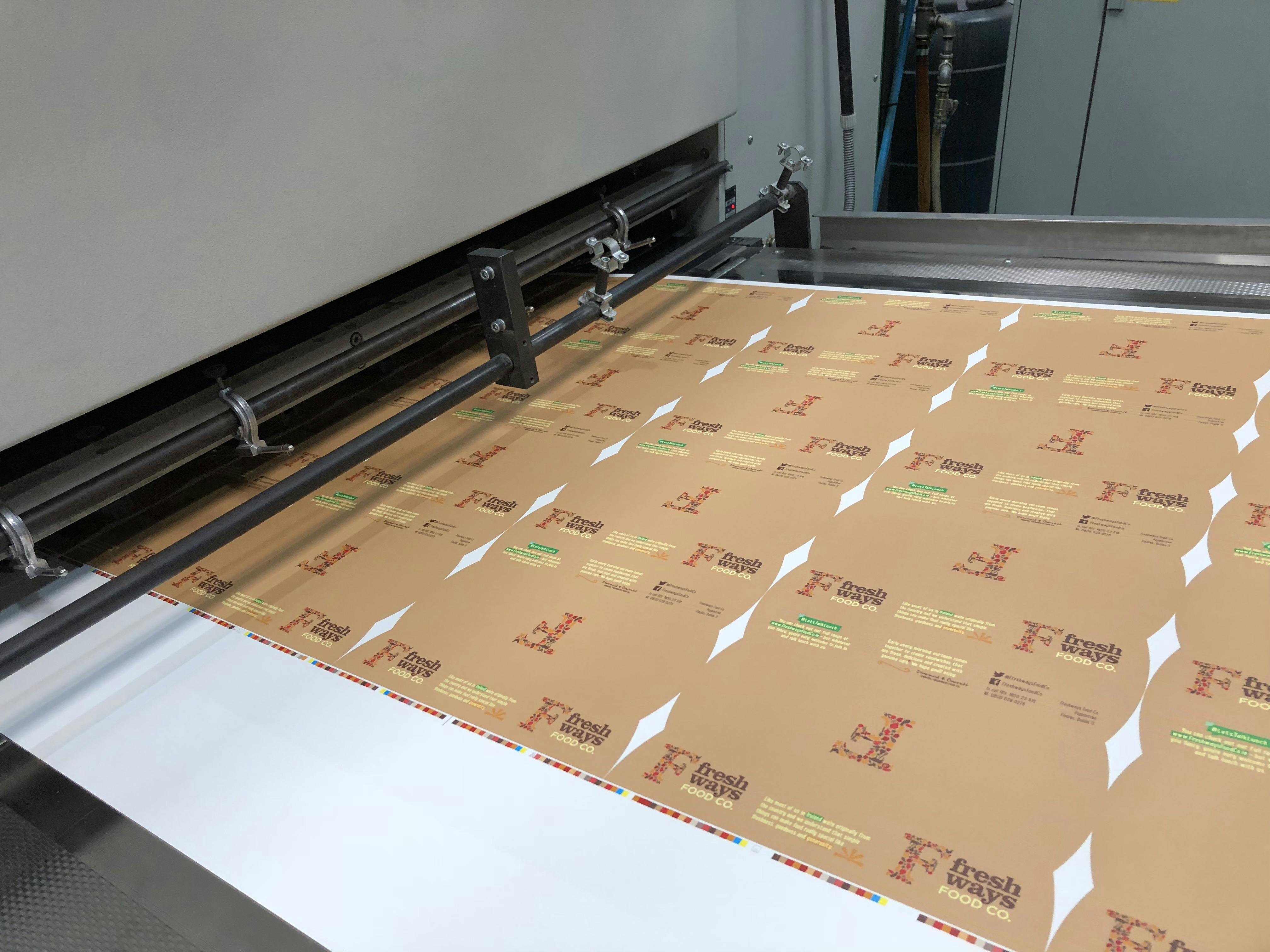

La finitura di stampati di alta qualità crea effetti straordinari e rende i prodotti più attraenti per gli acquirenti nel punto vendita. L’aspetto superiore è supportato e protetto laminando la superficie con un diverso foglio di finitura. Gli adesivi per questa applicazione devono fornire un’eccellente adesione alle pellicole e ai substrati stampati. Negli ultimi anni, Jowat ha sviluppato un’ampia gamma di adesivi a dispersione. Questi moderni adesivi lamellari sono caratterizzati da una quantità minima di schiuma e quantità di applicazione e da eccellenti proprietà di flusso. L’elevata resistenza e resistenza al taglio e la lunga durata assicurano processi di discesa ottimali, come scanalature, intagli o goffrature.

Products from the Jowacoll® 764.xx product group have been consistently optimised over the last years to improve their performance, for instance mechanical processing characteristics, cutting resistance, coating weight, gloss, and resistance to mechanical stress, e.g. due to embossing or fold burning. In addition, the new product generation also includes several adhesives that are approved for food contact. Which of the modern laminating adhesives is the best fit for an application depends on the machine type and the application method used, as well as on the specific requirements. However, the adhesive choice can also be influenced by what type of paper or film is to be bonded and by whether it has been printed conventionally or digitally.

The table below provides an overview of our dispersion adhesives from the product series Jowacoll® for laminating printed sheets. The product range comprises different product types with special performance characteristics adapted to the general process requirements in laminating applications.The products have been developed to meet the different requirements which arise from the production process as well as from the different carrier substrates and lamination materials. If the laminated compound is exposed to high mechanical stress during downline processing or if the films to be processed have a high rigidity (e.g. PET or acetate films), it is advisable to add 1.5 – 5 % of crosslinking agent Jowat® 195.70 or 195.79 in the case of food packaging.

Informazioni sul prodotto

- adhesive

- crosslinking agent

adhesive

crosslinking agent

I prodotti elencati rappresentano solo una selezione limitata del portafoglio di prodotti disponibile. La disponibilità del prodotto potrebbe variare in base alla regione. I dati tecnici, le caratteristiche e il campo di applicazione riportati nella tabella delineano le differenze tra i singoli adesivi del portafoglio prodotti. Il nostro dipartimento di tecnologia applicativa ei nostri rappresentanti di vendita sono a disposizione per fornire consulenza e supportarti nella ricerca dell'adesivo migliore per la tua particolare applicazione.

Nota: le informazioni contenute in questa pagina si basano sui risultati dei test dei nostri laboratori nonché sull'esperienza acquisita sul campo e non costituiscono in alcun modo alcuna garanzia di proprietà. A causa della vasta gamma di diverse applicazioni, substrati e metodi di lavorazione al di fuori del nostro controllo, nessuna responsabilità può essere derivata da queste indicazioni né dalle informazioni fornite dal nostro servizio di consulenza tecnica gratuito. Sono assolutamente necessari test dei clienti in condizioni quotidiane, test di idoneità alle normali condizioni di lavorazione e test adeguati allo scopo. Per le specifiche e ulteriori informazioni fare riferimento alle ultime schede tecniche.

Notizie ed articoli

From a chemical point of view, film laminating adhesives of the Jowacoll® 764.xx series are dispersion adhesives based on acrylate copolymers. They…

Jowat SE reacts to the present market demands with dispersion adhesives suited for food contact according to EU guideline 1935/2004

Adhesives and varnishes used in the manufacture and finishing of packaging materials have to provide more than just a strong bond. They also must be…

Detmold. 17th September 2015 - A new lighthouse product from Jowat, a 1-component dispersion takes the lead among water-based adhesives for printing…