Applikation Beskrivning

Trenden mot individuell och särpräglad design och därmed följande ökande materialmångfald, kombinerat med ständigt snabbare processcykler vid industriell serieproduktion, innebär stora bearbetningsutmaningar vid tillverkning av dörrar, men även för limmet som används. Dessutom måste produkten och limmet uppfylla olika krav beroende på vilken typ av dörr somt tillverkas. Dörrblad lamineras med klassisk faner i riktigt trä eller moderna materialkombinationer med hjälp av vitlim och smältlim som har optimerats för den enskilda processen. Alla limsystem har olika fördelar.

Produktinformation

- hot melt adhesive

- reactive hot melt adhesive

hot melt adhesive

reactive hot melt adhesive

Nyheter och artiklar

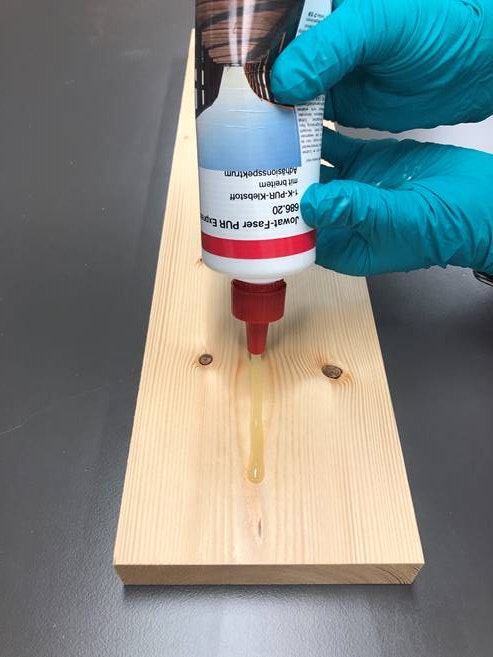

Jowat Manual: PUR prepolymer adhesives

Liquid, reactive polyurethane prepolymer adhesives (short: PUR prepolymers) are high-performance adhesives characterised by a broad spectrum of adhesion and bonding properties. PUR prepolymers are established problem-solvers that facilitate the reliable bonding of different materials and material combinations. Due to their benefits, these adhesives are used in many industries, in particular in load-bearing glulam applications, in the wood, construction and furniture industries, in the manufacture of caravans, in shipbuilding, in the automotive sector and in many other industries. Reactive polyurethane prepolymers are chemically crosslinking and curing adhesives, available as one-component or two-component products.

Benefits of one-component (1C) PUR prepolymer adhesives

- good penetration into the substrate

- no mixing necessary, easy processing

- fast curing at room temperature

- free of formaldehyde and solvents

- emission-free and odourless after complete curing

- good resistance to water and temperature

- high bond strengths