Applikation Beskrivning

Nyheter och artiklar

News

Jowat Manual with Tips and How To Guide - we help you finding the solution to your PUR cleaning problems

Professionella artiklar

For many years, lacquering and decor foil lamination have been established finishing methods in the manufacture of wood-based materials for the…

Professionella artiklar

The demand for environmentally compatible and harmless furnishings has constantly grown over the past years. Architects and interior fitters now have…

Pressmeddelande

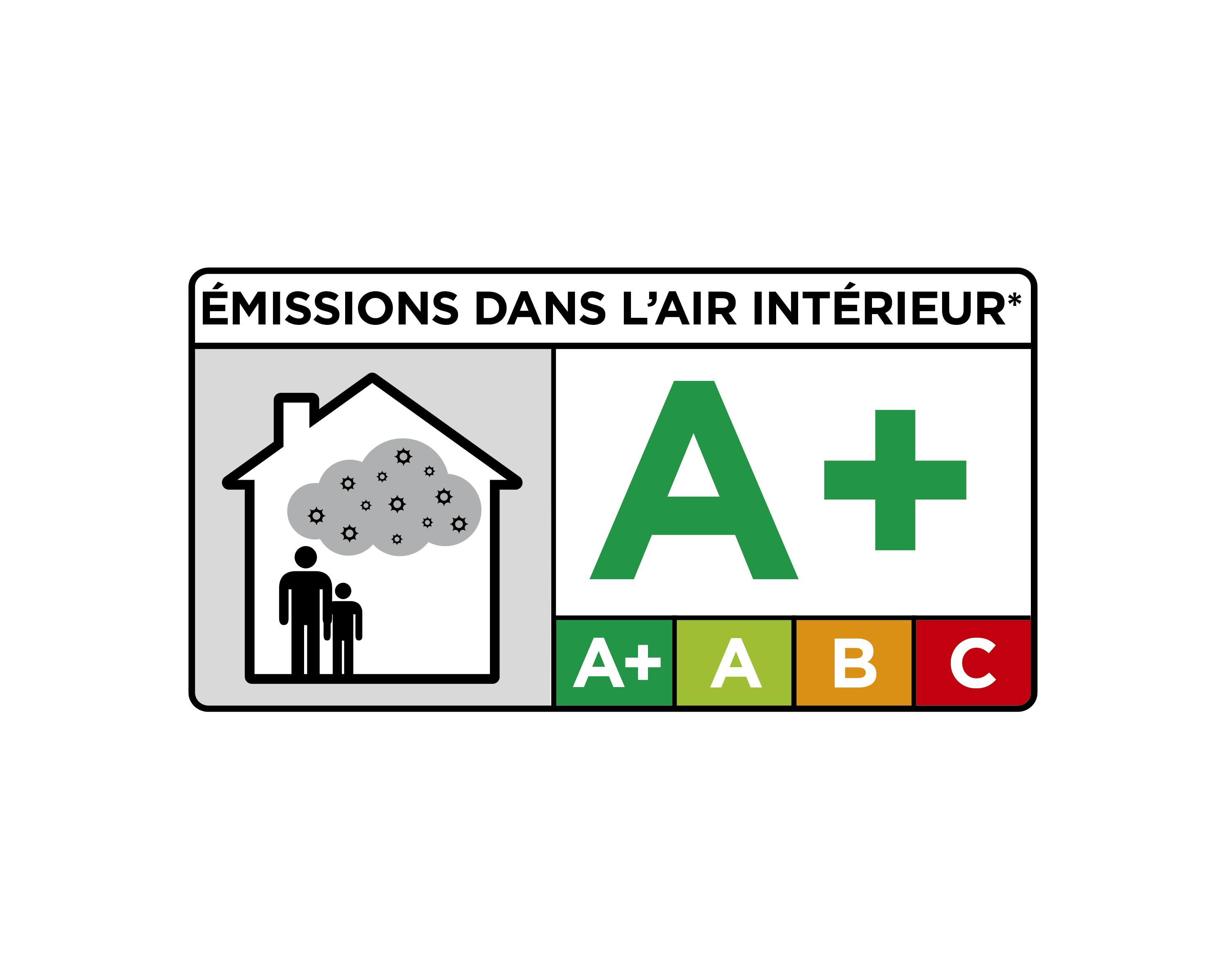

A new Jowat dispersion adhesive received the highest classification A+ from “Émissions dans l’air interieur,” currently the strictest rating system in…