Application Description

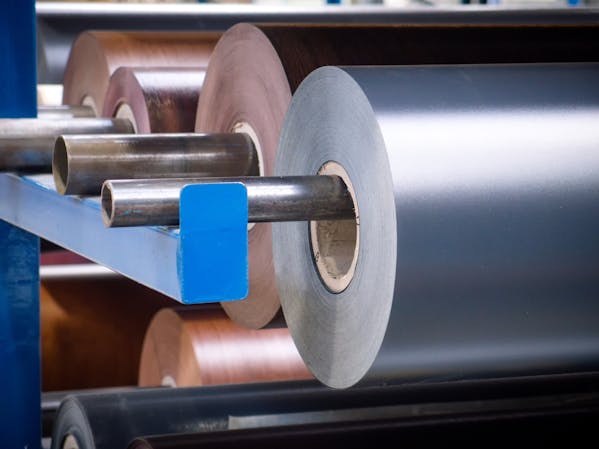

The adhesive technology has to meet constantly rising demands. More and more, the range of materials is expanded to include products that will not allow bonding without additional surface pretreatment. Often the application of a special primer is the most suitable - and often the only - method of achieving optimum adhesion on the respective substrate. This is a challenge which Jowat SE has met successfully for many years. Primers represent an important partner in adhesive bonding, and require a substantial measure of developing know-how and proficiency from the processor. The utilization of a primer leads to a major improvement of the bonding capacity of a surface. And this on the basis of a primer coating which a thickness of only a few micrometers.

Primers usually are employed when other pretreatments fail to reach the desired success, do not remain effective over an extended period of time, or cannot be integrated into an industrial bonding process. Primers mainly improve the adhesion between the surface of the bonding partners and the adhesive itself. Often they also serve to delay ageing processes, and in consequence clearly improve the durability of a bond, for instance due to the fact that a migration of water or other media into the adhesive is made substantially more difficult or even prevented entirely.

In a finishing process, the primer is often an almost invisible, but still unavoidable auxiliary agent. It allows processing of difficult substrates and a huge variety of materials on the same machine, but does not require a change of adhesive specific for the material. To sum up the advantages: A primer application makes the manufacturing processes more stable and efficient. In consequence, primers may offset the additional costs for their application.

Selecting the correct primer requires a wide technical knowledge on the adhesives in the specific case (whether water-based dispersions, reactive or non-reactive hot melt adhesives etc.). Apart from extensive information concerning the large variety of materials processed (like PVC, ABS, PP, PET, PMMA, aluminum, stainless steel), the application technology in use is a factor of equal importance for the optimum efficiency of a primer. Jowat provides a wide range of solvent- and water-based primers for edgebands and foils used in the wood and plastics processing industry. Following the changed classification of raw materials according to Reach and the resulting labelling requirements, Jowat supplies primers, which are free of e.g. NMP, NEP, THF and toluene. Modern primer systems meet the demands of customers and processors such as for instance IKEA.

Product Information

- solvent based primer

- water based primer

solvent based primer

| Base | Viscosity [mPas] / Temperature [°C] | Viscosity [s] / Temperature [°C] | Solids [%] | Adhesion to Substrates |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|

| Jowat® 406.09 | Primer | 140 ± 5 / 20 | 15,5 ± 1,5 | PVC, ABS | de en | |

| Jowat® 406.19 | PU/PVC | 140 ± 5 / 20 | 15,5 ± 1,5 | PVC, ABS | de en fr | |

| Jowat® 406.41 | PU/PVC | 140 ± 5 / 20 | 15,5 ± 2 | PVC | de en | |

| Jowat® 407.16 | EVA/PVC | 240 ± 50 / 20 | 15,0 ± 3,0 / 90 | de en | ||

| Jowat® 408.20 | Primer | 35 ± 2 / 20 | 13 ± 1,5 / 90 | ABS, PP, PET | de en fr | |

| Jowat® 408.48 | PU | 53,5 ± 2,5 / 20 | 13 ± 1,5 / 90 | PP, PET, ABS | de en | |

| Jowat® 408.40 | PU | 35 ± 5 / 20 | 15 ± 2 / 90 | ABS, PP | de en |

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are necessary. For the specifications as well as further information, please refer to the latest technical data sheets.