Descripción de la aplicación

Revestimiento de perfiles con adhesivos termofusibles

En la moderna fabricación de muebles e interiores ya no se conciben los perfiles sin revestimiento. Ya sean perfiles de muebles, molduras, zócalos, bastidores de cajones, paneles de pared y techo, marcos y muescas de puertas u otro tipo de perfiles de cualquier tipo, la colocación de los materiales de soporte más diversos con una variedad aparentemente ilimitada de materiales de laminado es la técnica más actual.

Como perfiles de soporte se emplean la madera maciza, los materiales a base de madera, los plásticos y también cada más el aluminio y otros metales.

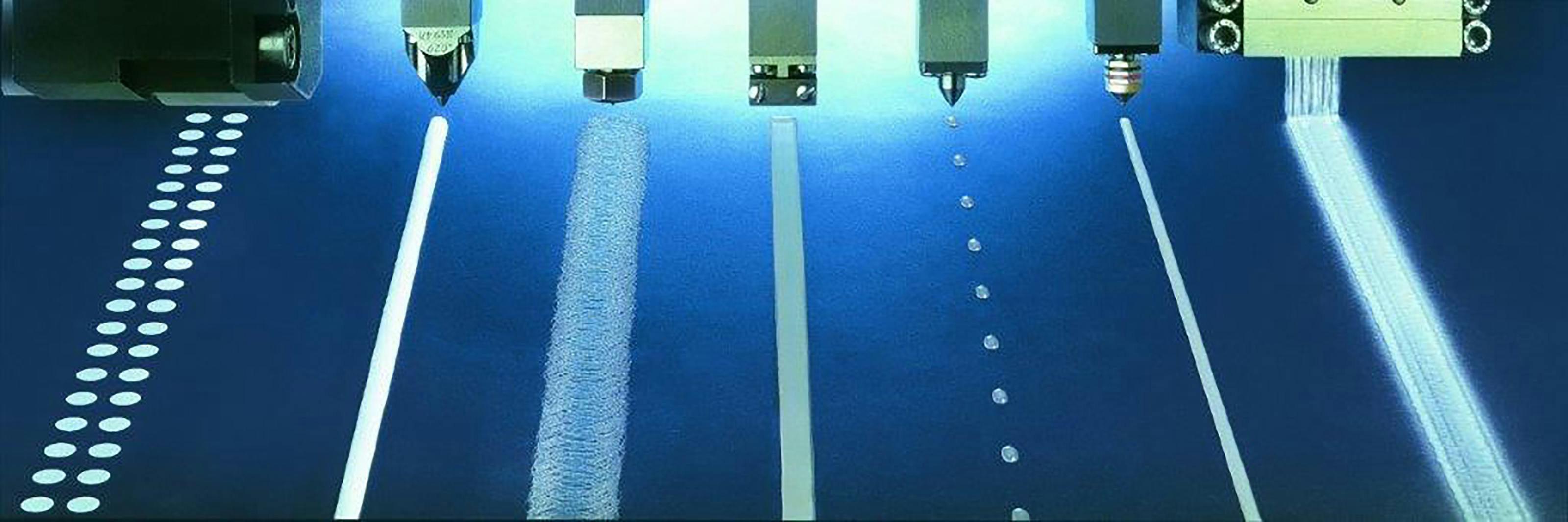

Incluso la técnica de aplicación de los adhesivos continúa evolucionando constantemente. Así, hoy en día se emplean preferentemente boquillas de ranura ancha regulable. Las velocidades de avance se han multiplicado parcialmente en los últimos años y hoy en día alcanzan hasta 100 m/min en instalaciones modernas.

Información del Producto

- PO hot melt adhesive

- EVA hot melt adhesive

- PUR hot melt adhesive

PO hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowat-Toptherm® 221.80 | PO Hot Melt Adhesive | 11550 ± 2050 / 200 | 180 - 200 | 115 ± 5 | 0,90 ± 0,02 / 20 | 15 ± 2 / 190 / 120 | de en fr |

| Jowat-Toptherm® 236.50 | PO Hot Melt Adhesive | 8000 ± 2000 / 200 | 180 - 200 | 110 ± 5 | 0,87 ± 0,02 / 20 | 15 ± 2 / 190 / 120 | de en fr |

| Jowat-Toptherm® 236.70 | PO Hot Melt Adhesive | 21000 ± 2500 / 200 | 180 - 200 | 115 ± 5 | 0,89 ± 0,02 / 20 | 12 ± 2 / 190 / 120 | de en fr |

| Jowat-Toptherm® 221.00 | PO Hot Melt Adhesive | 23200 ± 2200 / 200 | 115 ± 5 | 0,90 ± 0,03 / 20 | de en fr | ||

| Jowat-Toptherm® 224.00 | PO Hot Melt Adhesive | 4300 ± 900 / 200 | 170 - 190 | 95 ± 5 | 0,90 ± 0,02 / 20 | de en |

EVA hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowatherm® 280.30/31 | EVA Hot Melt Adhesive | 50500 ± 12500 / 200 | 180 - 200 | 90 ± 5 | 1,03 ± 0,03 / 20 | 6 ± 2 / 190 / 200 | de en fr |

| Jowatherm® 282.30 | EVA Hot Melt Adhesive | 12150 ± 3600 / 200 | 160 - 180 | 75 ± 5 | 1,31 ± 0,05 / 20 | 18 ± 3 / 160 / 200 | de en fr |

| Jowatherm® 291.45 | EVA Hot Melt Adhesive | 5500 ± 1275 / 200 | 170 - 190 | 85 ± 5 | 1,04 ± 0,03 / 20 | 18 ± 2 / 180 / 120 | de en fr |

| Jowatherm® 291.60 | EVA Hot Melt Adhesive | 5550 ± 1270 / 200 | 170 - 190 | 80 ± 5 | 1,00 ± 0,02 / 20 | 6 ± 2 / 180 / 120 | de en fr |

| Jowatherm® 293.50 | EVA Hot Melt Adhesive | 5500 ± 2000 / 200 | 180 - 200 | 85 ± 5 | 1,17 ± 0,05 / 20 | 4 ± 2 / 190 / 120 | de en |

PUR hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowatherm-Reaktant® 605.10 | PUR Hot Melt Adhesive | 41500 ± 13500 / 140 | 110 - 140 | 60 ± 5 | 1,1 ± 0,1 / 23 | 30 ± 5 / 140 | de en fr |

| Jowatherm-Reaktant® 605.20 | PUR Hot Melt Adhesive | 35000 ± 6800 / 140 | 140 | 60 ± 10 | 1,1 ± 0,1 / 23 | 25 ± 10 / 140 | de en fr |

| Jowatherm-Reaktant® 605.65 | PUR Hot Melt Adhesive | 37500 ± 7500 / 140 | 130 - 150 | 60 ± 5 | 1,1 ± 0,1 / 23 | 32 ± 5 / 140 | de en fr |

| Jowatherm-Reaktant® 605.80 | PUR Hot Melt Adhesive | 23000 ± 5000 / 140 | 120 - 140 | 65 ± 5 | 1,1 ± 0,1 / 23 | 9 ± 3 / 140 | de en fr |

| Jowatherm-Reaktant® 608.00/01 | PUR Hot Melt Adhesive | 90000 ± 20000 / 120; 42500 ± 7500 / 140 | 100 - 120 | 65 ± 5 | 1,1 ± 0,1 / 23 | 8 ± 2 / 140 | de en fr |

| Jowatherm-Reaktant® MR 608.90 | Monomer-Reduced PUR Hot Melt Adhesive | 60000 ± 20000 / 140 | 120 - 140 | 70 ± 5 | 1,1 ± 0,1 | de en fr | |

| Jowatherm-Reaktant® MR 605.90 | Monomer-Reduced PUR Hot Melt Adhesive | 22500 ± 7500 / 140 | 130 - 150 | 1.1 ± 0.1 / 20 | de en fr |

Los productos enumerados solo representan una selección limitada de la cartera de productos disponible. La disponibilidad del producto puede variar según la región. Los datos técnicos, las características y el campo de aplicación proporcionados en la tabla describen las diferencias entre los adhesivos individuales de la cartera de productos. Nuestro Departamento de Tecnología de Aplicación y nuestros Representantes de Ventas están disponibles para brindarle asesoramiento y ayudarlo a encontrar el mejor adhesivo para su aplicación particular.

Nota: La información de esta página se basa en los resultados de las pruebas de nuestros laboratorios, así como en la experiencia adquirida en el campo, y de ninguna manera constituye una garantía de propiedades. Debido a la amplia gama de diferentes aplicaciones, sustratos y métodos de procesamiento fuera de nuestro control, no se puede derivar ninguna responsabilidad de estas indicaciones ni de la información proporcionada por nuestro servicio gratuito de asesoramiento técnico. Las pruebas del cliente en las condiciones diarias, las pruebas de idoneidad en las condiciones normales de procesamiento y las pruebas de ajuste adecuadas para el propósito son absolutamente necesarias. Para obtener las especificaciones y más información, consulte las fichas técnicas más recientes.

News & Articles

Jowat Manual with Tips and How To Guide for cleaning problems and helpful tips for adhesive changes

Jowat Manual with Tips and How To Guide for cleaning problems and helpful tips for adhesive changes

otras aplicaciones

Otras aplicaciones en el campo de „Industria del mueble”

- Adhesión de cantos

- Laminado de superficies

- 3D lamination

- Postforming | Worktop sealing

- Primer

- Dowelling and frame bonding

- Rack production

- Upholstery

- Assembly of pocket spring mattresses

- Manufacture of foam mattresses

- Foam lamination

- Assembly bonding (furniture/interior)

- Laminado textil (tejidos de cubierta)

- Embalaje