Applikation Beskrivning

Ommantling av profiler

Belagda profiler accepteras idag som standardkomponenter vid tillverkning av moderna möbler och interiördetaljer. Oavsett om det handlar om möbeldekor, golvlister, taklister, hurtsstommar, vägg- och takpaneler, dörrkarmar eller andra typer av profiler är ommantling av profiler på de mest skilda material ett hett ämne idag. Beläggningsmaterialen kan vara av alla typer - det finns en nästan oändlig variation av folier, papper och fanermaterial.

Substratmaterialen som beläggs kan vara av de mest skilda slag. Det kan handla om massivt trä, träbaserade underlag, plast och (allt vanligare) profiler av aluminium och andra metaller.

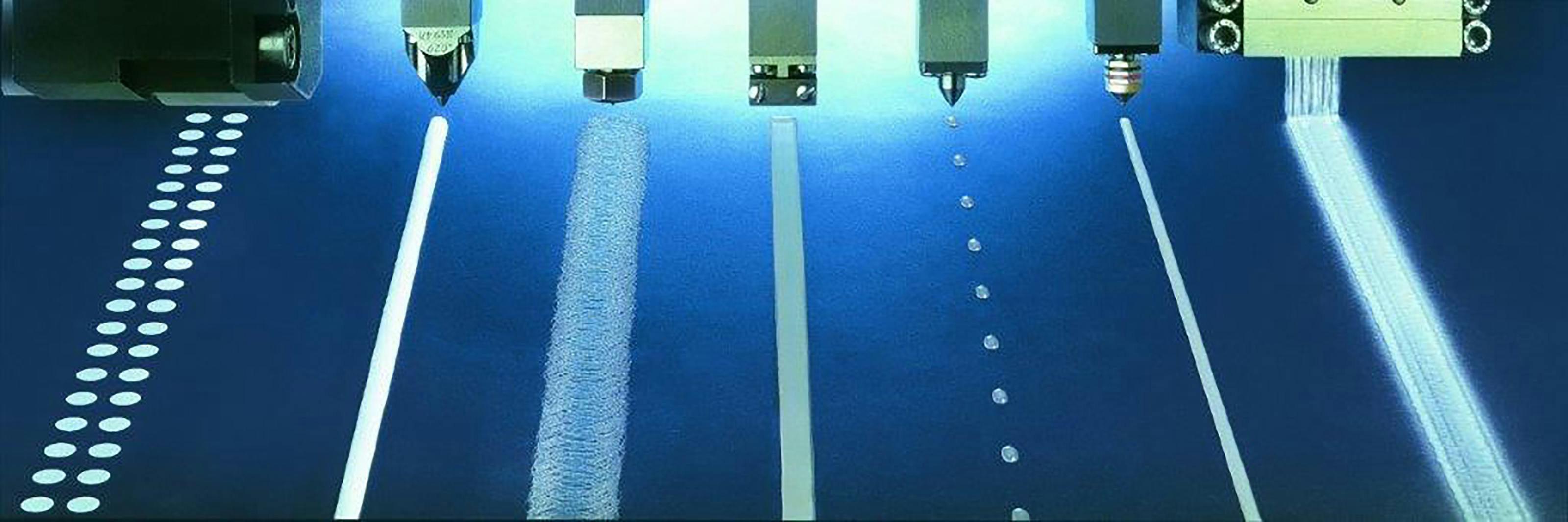

Tekniken för att applicera lim utvecklas också kontinuerligt. Den vanligaste tekniken idag är spaltmunstycken med variabel bredd. Linjehastigheterna har i en del fall flerfaldigats under de senaste åren. Moderna linjer når hastigheter upp till 100 m/min.

Produktinformation

- PO hot melt adhesive

- EVA hot melt adhesive

- PUR hot melt adhesive

PO hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowat-Toptherm® 221.80 | PO Hot Melt Adhesive | 11550 ± 2050 / 200 | 180 - 200 | 115 ± 5 | 0,90 ± 0,02 / 20 | 15 ± 2 / 190 / 120 | de en fr |

| Jowat-Toptherm® 236.50 | PO Hot Melt Adhesive | 8000 ± 2000 / 200 | 180 - 200 | 110 ± 5 | 0,87 ± 0,02 / 20 | 15 ± 2 / 190 / 120 | de en fr |

| Jowat-Toptherm® 236.70 | PO Hot Melt Adhesive | 21000 ± 2500 / 200 | 180 - 200 | 115 ± 5 | 0,89 ± 0,02 / 20 | 12 ± 2 / 190 / 120 | de en fr |

| Jowat-Toptherm® 221.00 | PO Hot Melt Adhesive | 23200 ± 2200 / 200 | 115 ± 5 | 0,90 ± 0,03 / 20 | de en fr | ||

| Jowat-Toptherm® 224.00 | PO Hot Melt Adhesive | 4300 ± 900 / 200 | 170 - 190 | 95 ± 5 | 0,90 ± 0,02 / 20 | de en |

EVA hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowatherm® 280.30/31 | EVA Hot Melt Adhesive | 50500 ± 12500 / 200 | 180 - 200 | 90 ± 5 | 1,03 ± 0,03 / 20 | 6 ± 2 / 190 / 200 | de en fr |

| Jowatherm® 282.30 | EVA Hot Melt Adhesive | 12150 ± 3600 / 200 | 160 - 180 | 75 ± 5 | 1,31 ± 0,05 / 20 | 18 ± 3 / 160 / 200 | de en fr |

| Jowatherm® 291.45 | EVA Hot Melt Adhesive | 5500 ± 1275 / 200 | 170 - 190 | 85 ± 5 | 1,04 ± 0,03 / 20 | 18 ± 2 / 180 / 120 | de en fr |

| Jowatherm® 291.60 | EVA Hot Melt Adhesive | 5550 ± 1270 / 200 | 170 - 190 | 80 ± 5 | 1,00 ± 0,02 / 20 | 6 ± 2 / 180 / 120 | de en fr |

| Jowatherm® 293.50 | EVA Hot Melt Adhesive | 5500 ± 2000 / 200 | 180 - 200 | 85 ± 5 | 1,17 ± 0,05 / 20 | 4 ± 2 / 190 / 120 | de en |

PUR hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowatherm-Reaktant® 605.10 | PUR Hot Melt Adhesive | 41500 ± 13500 / 140 | 110 - 140 | 60 ± 5 | 1,1 ± 0,1 / 23 | 30 ± 5 / 140 | de en fr |

| Jowatherm-Reaktant® 605.20 | PUR Hot Melt Adhesive | 35000 ± 6800 / 140 | 140 | 60 ± 10 | 1,1 ± 0,1 / 23 | 25 ± 10 / 140 | de en fr |

| Jowatherm-Reaktant® 605.65 | PUR Hot Melt Adhesive | 37500 ± 7500 / 140 | 130 - 150 | 60 ± 5 | 1,1 ± 0,1 / 23 | 32 ± 5 / 140 | de en fr |

| Jowatherm-Reaktant® 605.80 | PUR Hot Melt Adhesive | 23000 ± 5000 / 140 | 120 - 140 | 65 ± 5 | 1,1 ± 0,1 / 23 | 9 ± 3 / 140 | de en fr |

| Jowatherm-Reaktant® 608.00/01 | PUR Hot Melt Adhesive | 90000 ± 20000 / 120; 42500 ± 7500 / 140 | 100 - 120 | 65 ± 5 | 1,1 ± 0,1 / 23 | 8 ± 2 / 140 | de en fr |

| Jowatherm-Reaktant® MR 608.90 | Monomer-Reduced PUR Hot Melt Adhesive | 60000 ± 20000 / 140 | 120 - 140 | 70 ± 5 | 1,1 ± 0,1 | de en fr | |

| Jowatherm-Reaktant® MR 605.90 | Monomer-Reduced PUR Hot Melt Adhesive | 22500 ± 7500 / 140 | 130 - 150 | 1.1 ± 0.1 / 20 | de en fr |

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.

News & Articles

Jowat Manual with Tips and How To Guide for cleaning problems and helpful tips for adhesive changes

Jowat Manual with Tips and How To Guide for cleaning problems and helpful tips for adhesive changes