Product Description

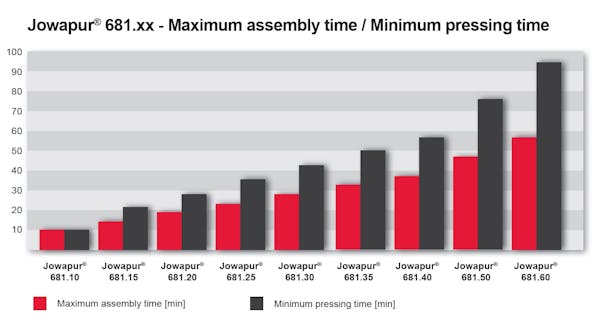

The choice of an adhesive system has a major effect on the efficiency of the manufacturing process of load- bearing building elements. The adhesive product line Jowapur® 681.xx (adhesives Jowapur® 681.10 up to 681.60) provides manufacturers with the possibility to choose the product that best matches their requirements and to optimally design their production processes. Due to a very good ratio between assembly times and pressing times, Jowapur® 681.xx opens up completely new possibilities and facilitates a capacity increase as well as higher process reliability in the manufacture of load-bearing glulam, without the need for additional investments.

Shorter pressing times can increase machine productivity and therefore lower the costs of the existing manufacturing processes. Planers of new systems can design procedures with more flexibility and optimise the capital expenditure accordingly. The reinforcing fibres contained in the adhesives provide a major advantage during manufacturing, when the load-bearing glulam parts are laminated and fingerjointed. For instance, the fibres minimise the sliding apart of non-cured fingerjointed assemblies when they are transferred to the interim storage for curing as well as the lateral shift of the timber during pressing in glulam production. Adhesives from the Jowapur® 681.xx series are free of formaldehyde and solvents, and are also emission-free and odourless after complete curing.

Application Description

Jowapur® 681.xx is a joint-filling, fibre-reinforced one-component adhesives series based on polyurethane with an optimal fibre geometry. It cures with wood moisture and/or ambient humidity to create a water-insoluble resin, and is used for manufacturing load-bearing timber.

Technical Data

-

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.