Descrizione

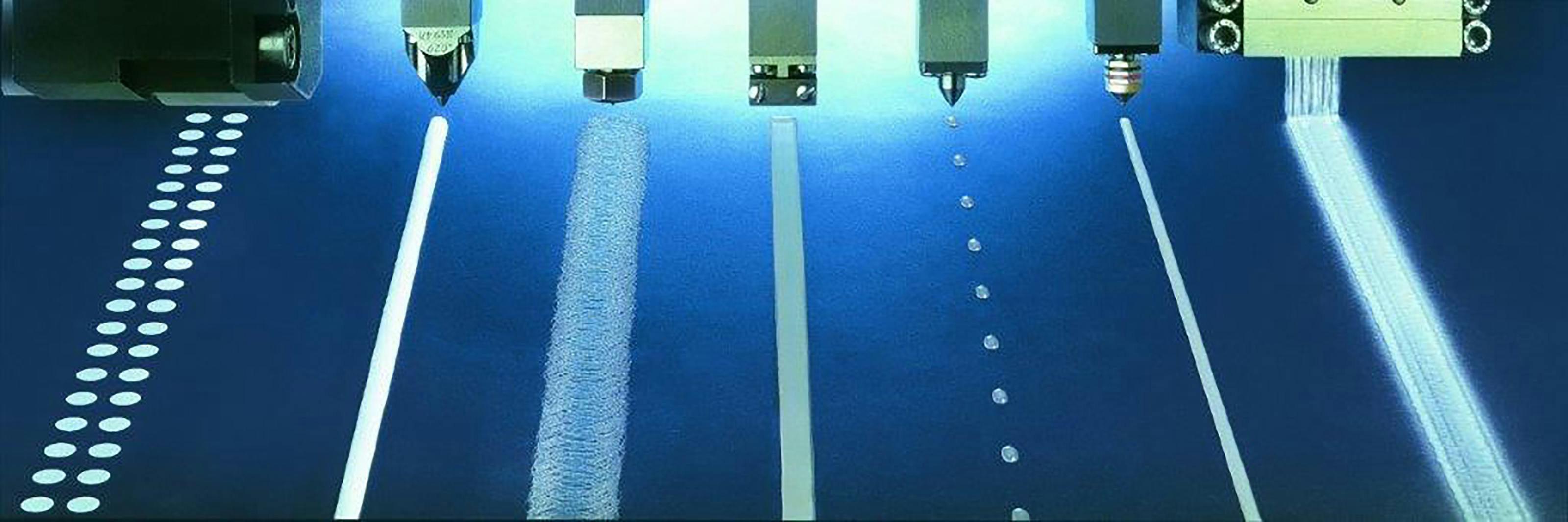

I filtri per l’abitacolo delle autovetture devono fornire aria pulita all’interno del veicolo, a tal fine durante il ciclo produttivo vengono uniti diversi materiali. I materiali filtranti uniti con questo sistema proteggono i passeggeri da polvere, polline, batteri, odori, ed anche da gas inquinanti come benzene ed ozono. Quando si considera la vivibilità di un veicolo, questi filtri giocano un ruolo importante. Una lunga vita dei prodotti e il mantenimento del loro pieno potere filtrante fino al momento della sostituzione, sono delle necessità basilari per un basso consumo di carburante e per evitare danni al sistema di climatizzazione.

Ciò significa che gli adesivi utilizzati non devono, in nessun modo, impattare la funzionalità dei filtri.

Informazioni sul prodotto

-

I prodotti elencati rappresentano solo una selezione limitata del portafoglio di prodotti disponibile. La disponibilità del prodotto potrebbe variare in base alla regione. I dati tecnici, le caratteristiche e il campo di applicazione riportati nella tabella delineano le differenze tra i singoli adesivi del portafoglio prodotti. Il nostro dipartimento di tecnologia applicativa ei nostri rappresentanti di vendita sono a disposizione per fornire consulenza e supportarti nella ricerca dell'adesivo migliore per la tua particolare applicazione.

Nota: le informazioni contenute in questa pagina si basano sui risultati dei test dei nostri laboratori nonché sull'esperienza acquisita sul campo e non costituiscono in alcun modo alcuna garanzia di proprietà. A causa della vasta gamma di diverse applicazioni, substrati e metodi di lavorazione al di fuori del nostro controllo, nessuna responsabilità può essere derivata da queste indicazioni né dalle informazioni fornite dal nostro servizio di consulenza tecnica gratuito. Sono assolutamente necessari test dei clienti in condizioni quotidiane, test di idoneità alle normali condizioni di lavorazione e test adeguati allo scopo. Per le specifiche e ulteriori informazioni fare riferimento alle ultime schede tecniche.

Notizie ed articoli

Interior filters for cars consist of multi-layer materials, such as activated carbon filter media. These have to be connected in such a way that the…

A new pleating adhesive from Jowat for the manufacture of building ventilation filters impresses with top performance and favourable conditions.

Jowat Manual with Tips and How To Guide for cleaning problems and helpful tips for adhesive changes

In the manufacture of air filters, user-friendly, intelligent adhesives are a crucial factor for process efficiency and make air filter systems…