Application Description

Laminates

For years, laminate has been one of the most demanded flooring materials. And there is good reason why: It is easy to maintain, combines many practical characteristics, such as resistance to water and wear or footfall sound reduction, and is available at a relatively low cost. The wide range of decor foils facilitates all possible designs. High-quality laminate floors with embossed structures match the appearance of solid wood parquet floors and frequently also feel similar to a “real” wood floor.

Laminates are manufactured from a MDF or HDF core board which is laminated with a top layer consisting of a cut sheet or reel material after which the compound is pressed. In downline processing, the laminate may then be sealed or enhanced with special functions, for instance with an additional protective layer by applying a coating of scratch-resistant varnish.

Vinyl floors

Vinyl floors have also been established for many years for commercial as well as for private use. The flooring is manufactured by printing a decorative layer on a core layer made of MDF, plastic or cork which is then laminated with a PVC top layer. The reverse side is sealed or coated with special adhesives to make it water-repellent.

Design floors

Plastic-based design floors are the latest trend in floorings. There are virtually no limits to creativity in the manufacture of these floors. They can be laminated with transparent foils which may be equipped with further additional functions. Luxury Vinyl Tiles are available in a variety of formats from square tiles to boards in different sizes and offer the realistic look of natural materials like wood and stone but also ceramics, concrete or sand. PUR hot melts which have been developed particularly for this application play a major role in the manufacture of design floors.

The adhesive is applied by slot nozzles with adjustable widths on the reverse side of the foil to ensure a complete wetting of the surface and a smooth and even application pattern. Development in the manufacture of plasticiser-free floors has advanced fast and modern, PVC-free design floors are becoming established as an alternative to vinyl floors. In response, Jowat has developed an environmentally compatible adhesive. The new foil adhesive with reduced emissions for the lamination of foils and decor papers provides a major input into ecologically compatible and healthy living conditions.

Product Information

- dispersion

- PUR hot melt adhesive

dispersion

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Open Time [min] / Temperature [°C] | Density [g/cm³] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|

| Jowacoll® ER 147.00 | Foil Adhesive | 10000 / RT | 0 – 3 | 1,35 ± 0,05 / RT | de en fr | |

| Jowacoll® 148.00 | Foil Adhesive | 12000 ± 4000 / 20 | 0 – 3 | 1,35 ± 0,05 / RT | de en fr | |

| Jowacoll® 148.20 | Foil Adhesive | 23000 / 20 | 0 – 3 | 1,35 ± 0,05 / RT | de en fr | |

| Jowacoll® 148.70 | Foil Adhesive | 10000 / 20 | 0 - 4 | 1,25 ± 0,05 / RT | de en fr |

PUR hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Processing Temperature [°C] | Open Time [min] / Temperature [°C] | Density [g/cm³] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|

| Jowatherm-Reaktant® 603.80 | PUR Hot Melt Adhesive | 11000 ± 4500 / 120 | 110 - 130 | 0,4 / 120 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® 609.30 | PUR Hot Melt Adhesive | 15000 ± 3000 / 120 | 110 - 130 | 3 ± 1 / 120 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® 609.45 | PUR Hot Melt Adhesive | 31000 ± 11000 / 120 | 100 - 130 | 1 ± 0,2 / 120 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® 609.50 | PUR Hot Melt Adhesive | 25000 ± 5000 / 120 | 120 - 140 | 1 ,5 ± 0,5 / 120 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® 609.00 | PUR Hot Melt Adhesive | 17000 ± 5000 / 120 | 110 - 130 | 4 ± 1 / 120 | 1,1 ± 0,1 / 20 | de en fr |

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.

News & Articles

Since their development in the 1950s, dispersion glues have become the ideal partner for the wood and furniture industry as well as for woodworking…

Jowat Manual with Tips and How To Guide - we help you finding the solution to your PUR cleaning problems

For many years, lacquering and decor foil lamination have been established finishing methods in the manufacture of wood-based materials for the…

The demand for environmentally compatible and harmless furnishings has constantly grown over the past years. Architects and interior fitters now have…

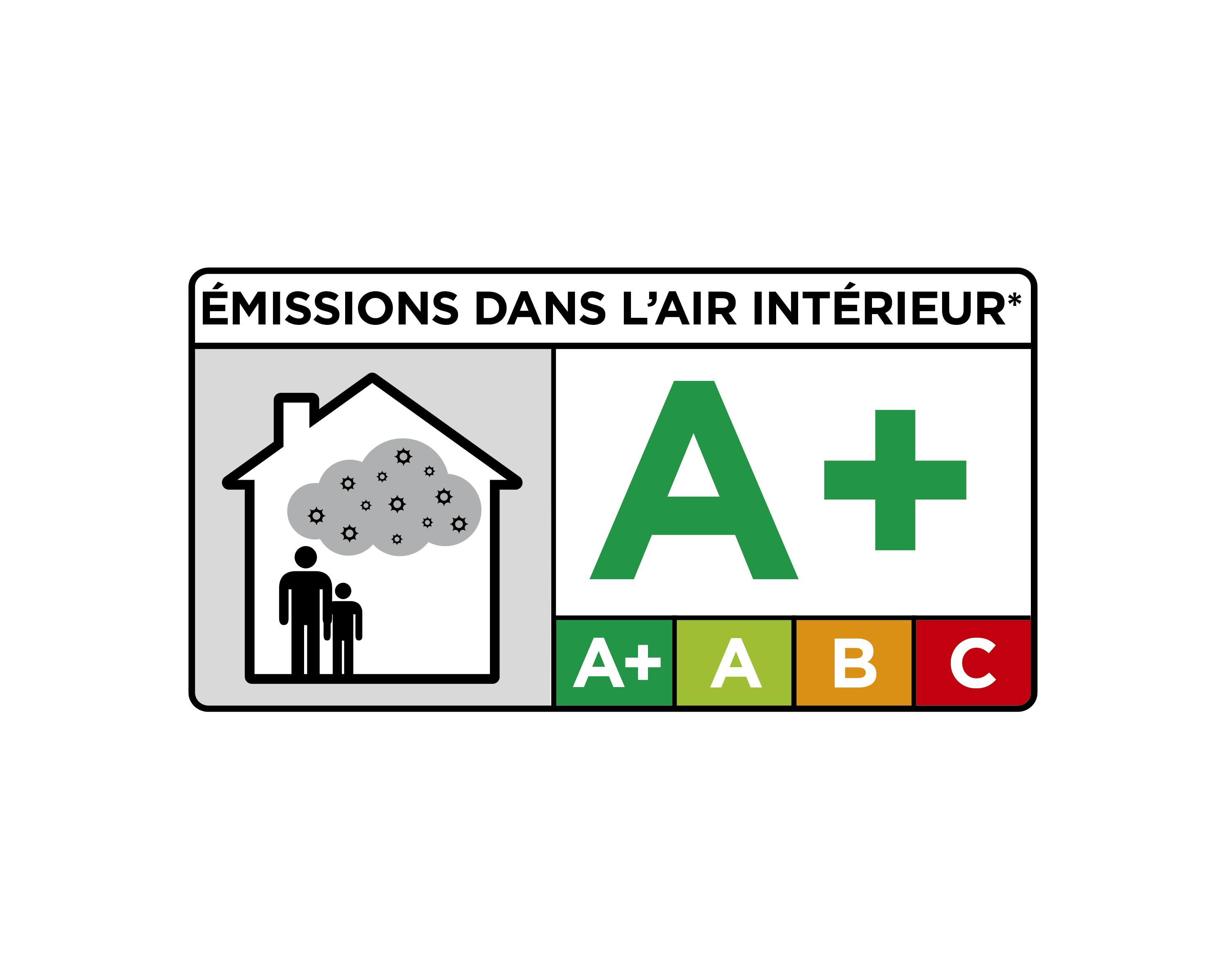

A new Jowat dispersion adhesive received the highest classification A+ from “Émissions dans l’air interieur,” currently the strictest rating system in…