Application Description

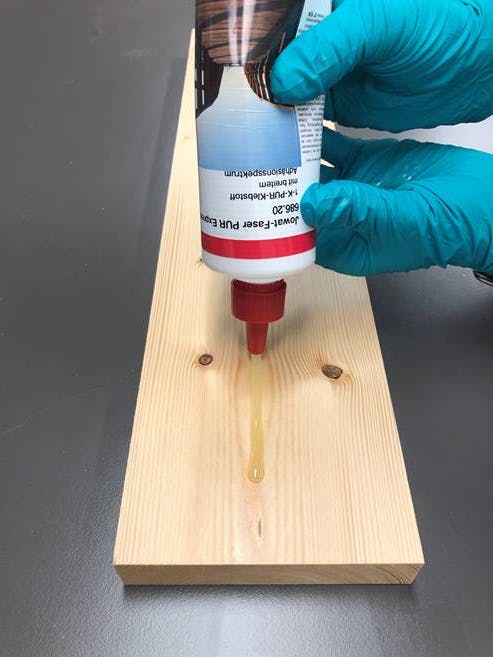

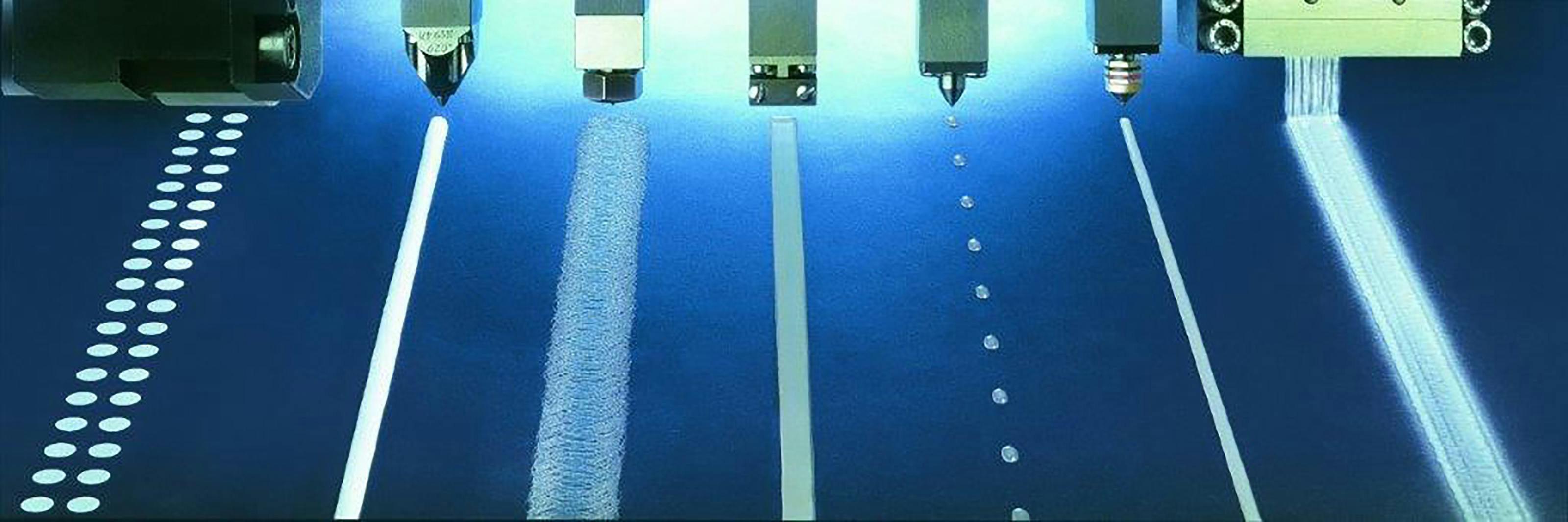

Whether as decorative cladding panels or as part of heat insulation – modern composites and sandwich elements play a key role in many applications. Intelligent high-performance adhesives have become indispensable in the manufacturing of these products due to the wide diversity of material combinations which have to be joined to meet different specifications. The broad spectrum of adhesion provided by special Jowat adhesives is essential to bonding different substrates such as wood, mineral materials, concrete, plastics and various insulation materials like mineral fibre, foams or aluminium foil. Apart from this, they also meet additional requirements regarding hydrolysis resistance, thermal stability, or fire protection. In addition to reactive polyurethane hot melt adhesives and one-component PUR prepolymer adhesives with different open times and initial strengths which have been tried and proven for many years in the manufacture of high-performance composite elements, two-component SE polymer adhesives from Jowat have also become established in this application. Adhesives from the latter product group are characterised by excellent adhesion, high strength, and permanently elastic bondlines which absorb the tensions between the materials in sandwich structures. Due to this, Jowat® SE polymers are reliable general-purpose products for manual and industrial assembly processes.

Jowat® SE polymers are two-component adhesive systems, which build a bridge between the powerful epoxy resins and the MS polymers with excellent adhesion properties. The full strength of this adhesive system is shown especially when difficult to adhere to surfaces must be bonded that are exposed to high stress. Due to the permanent elastic characteristics of the adhesive, these systems also reliably join substrates with different elasticity coefficients. Jowat® SE polymers are free of isocyanates and solvents.

Product Information

- 1-component adhesive

- hot melt adhesive

1-component adhesive

hot melt adhesive

The products listed only represent a limited selection of the available product portfolio. Product availability might differ by region. The technical data, characteristics and field of application provided in the table outline the differences between the individual adhesives of the product portfolio. Our Application Technology Department and our Sales Representatives are on hand to provide advice and support you finding the best adhesive for your particular application.

Note: The information on this page is based on test results from our laboratories as well as on experience gained in the field, and does in no way constitute any guarantee of properties. Due to the wide range of different applications, substrates, and processing methods beyond our control, no liability may be derived from these indications nor from the information provided by our free technical advisory service. Customer trials under everyday conditions, testing for suitability at normal processing conditions, and appropriate fit-for-purpose testing are absolutely necessary. For the specifications as well as further information, please refer to the latest technical data sheets.

News & Articles

Find out everything you need to know about handling PUR Prepolymer Adhesives. All details can be found in the attached PDF brochure.

Water is more than a necessity – it’s the basis of all life. To create an exhaustive drinking water supply, more and more regions around the world are…

Jowat Manual with Tips and How To Guide for cleaning problems and helpful tips for adhesive changes

Further Applications

在该领域的进一步应用 „Building Elements”

- Textile lamination (Building textiles)

- Spacers

- 复合板部件

- Precast concrete parts

- 窗户型材包覆

- Exterior doors

- Interior doors (Flat lamination)

- Wood windows manufacture

- Parquet manufacture

- Manufacture of laminate-, vinyl- and design flooring

- Access floor manufacture

- Textile floor coverings

- Profile wrapping (skirting boards)

- Appretur

- Insulation Materials