Product Description

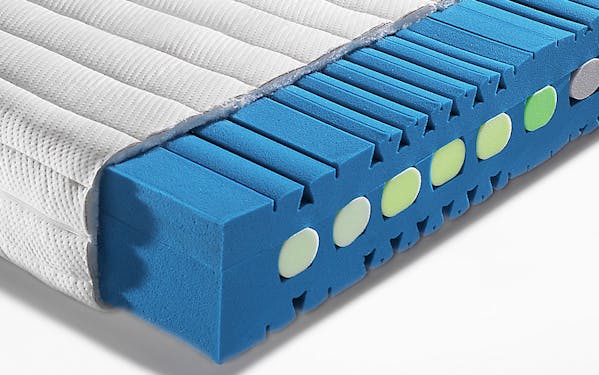

The requirements for a strong and durable bond in the manufacture of foam mattresses are constantly growing. For instance due to new materials and mattress compositions which are difficult to bond with standard adhesive systems.

Like in many other applications, reactive Polyurethane hot melt adhesives (PUR) provide major benefits for the bonding of foam mattresses due to the special characteristics of this product group. Jowatherm-Reaktant® 639.10 impresses with excellent bonding results on all established materials, especially on materials which are difficult to bond, such as latex, viscose or gel foam.

The PUR hot melt adhesive facilitates superior bonds and ensures long-term resistance. The bondline is permanently soft and meets highest expectations for quality and comfort.

Requirements regarding harmful substances according to IKEA, Oeko-Tex100, LGA, TÜV and Blue Angel are met. In general, the adhesive can be applied on one or both surfaces, by roller or spraying. For an even better bonding result, the application amount may be reduced significantly during two-sided application where allowed by the process and mattress construction.

Jowatherm-Reaktant® 639.10 also provides superior results with established materials (e.g. cold foam) and mattress constructions: The high initial strength ensures easy handling of the mattress before pressing as well as an easy filling and packaging process. In addition, process costs can be reduced and efficiency increased due to the immediate filling, packaging and shorter interim storage. Coupled with increased process reliability, these are major advantages of PUR hot melt adhesives in the assembly of mattresses.

Application Description

Jowatherm-Reaktant® 639.10 is an adhesive for the application by roller or spraying. For the assembly of foam mattresses as well as for foam lamination.

Product Features

✓ Benefits of Jowatherm-Reaktant® 639.10 in Foam Mattress Assembly Applications:

- 100 % solids content, no water used during bonding, immediate packaging possible

- Inline roll-packing of the mattress without long drying times, depending on mattress structure

- Less storage and production area necessary

- Reduced costs due to higher yield possible

- Storage and transport stable adhesive

- Foam layers may be repositioned

- Short pressing time

- High initial strength – easy handling of the mattress

- Very high heat resistance and compound strength due to chemical crosslinking

News & Articles

People are becoming increasingly aware of just how important it is to get a good night’s sleep. As a result, requirements for mattresses are becoming…

Application

Our product in use

Further Products

Följande produkter inom „Jowatherm-Reaktant® PUR Hot Melt Adhesive”

- Jowatherm-Reaktant® 609.00

- Jowatherm-Reaktant® 609.40

- Jowatherm-Reaktant® 603.80

- Jowatherm-Reaktant® 604.25 & Primer Jowat® 406.84

- Jowatherm-Reaktant® 605.62/65

- Jowatherm-Reaktant® 630.20

- Jowatherm-Reaktant® 630.80

- Jowatherm-Reaktant® 638.20

- Jowatherm-Reaktant® 607.40

- Jowatherm-Reaktant® 608.00

- Jowatherm-Reaktant® 613.18

- Jowatherm-Reaktant® 642.00/08

- Jowatherm-Reaktant® 604.35

- Jowatherm-Reaktant® 642.30

- Jowatherm-Reaktant® 609.30