Description

Primer, also called adhesion promoter or chemical bridges, function as a bonding layer between the substrate and the adhesive, and improve the adhesion. They are used mainly on surfaces which are difficult to bond or in applications with very high demands regarding resistance against moisture and heat. Many Jowat primers contain highly dispersed silica acid which expands the surface and facilitates a permanent bond.

Applying an primer which is compatible with the specific adhesive is often the most suitable or the only method to achieve an optimum adhesion to the substrate. In addition, the primer may also function as a barrier protecting the surface against infiltration of water or other external elements, and therefore significantly increase the ageing resistance and permanent tack of the surface finishing.

Primers are usually applied in a thin film to ensure a proper drying of the coating. Due to the long-lasting effect of the dried primer, the primer application and the bonding process can generally be carried out independently at different times. Depending on the material, some substrates may require an “oxidative pretreatment” before the primer is applied. Adhesion to the substrate and the cohesion of the primer film can be improved by mixing the primer with a crosslinking agent.

For some materials (e.g. PP), it is absolutely necessary to add a crosslinking agent.

Features

Primer provide the following benefits:

- universal use of adhesives

- adhesion to the most different materials

- permanent bonds to meet the strictest requirements

- frequently, preserving the surface pretreatment

Product series and characteristics

Jowat® Primer (water-based)

Basis: Polyurethane

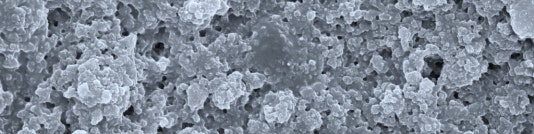

Properties: Water-based primers are physically curing systems. Polymer chains and highly dispersed silica acids are kept suspended in a liquid and provide the adhesive properties once the liquid has evaporated.

Packaging: Liquid; buckets, hobbocks, drums, IBC

Jowat® Primer (solvent-based)

Basis: Polyurethane; ethylene vinyl acetate; PVC

Properties: Solvent-based primers consist of polymers (also called binding agents) which are dissolved in a solvent, and dispersed silica acids which are the “solid component” in the polymer solution. The transition from the liquid processing state to the final solid state is facilitated by the solvent. It functions as a transport and processing agent for the binding agents and the silica acids, and is also aggressive enough to bite the surface of the primered substrate and to ensure the necessary bond strength during joining.

Jowat supplies a range of special solvent-based primers for a multitude of substrates, e.g. for PVC, ABS, PP and PET.

Application: Edgebands, (furniture) foils

Packaging: Liquid; buckets, hobbocks, drums, IBC

Jowat® Wash Primer (solvent-based)

Basis: Polyurethane; PVC

Properties: Solvent-based wash primers do not contain silica acids. Therefore, they can be applied by felt or vacuum systems. Wash primers are available as classic solvent-based formulations as well as so-called VOC-reduced primers. The latter have a VOC content between 20 and 49 percent, which is a maximum content 50 % lower compared to classic systems. Primers from this product line are mainly used for the pretreatment of PVC window profiles to remove extrusion rests and external lubricants from the surface.

Packaging: Liquid; canister, hobbocks, drums, IBC