Mô tả ứng dụng

Hệ thống keo dán hiện đại cho các bề mặt hoàn hảo

Trong sản xuất nội thất hiện đại, các tấm nền gỗ được cán bề mặt với nhiều vật liệu đa dạng nhất. Ngoài giấy trang trí tẩm nhựa và veneer, phôi nhựa nhiệt dẻo, CPL và HPL thường được sử dụng. Các vật liệu này được liên kết bằng cách sử dụng nhiều công nghệ khác nhau yêu cầu các giải pháp keo dán tối ưu cụ thể. Trong nhiều năm, keo Ure Formaldehyde (UF) là công nghệ được sử dụng. Chúng, tuy nhiên, được xem ngược với tăng trưởng, do các phương diện hiện thời về sức khỏe và sinh thái. Các hệ thống keo Jowat tiên tiến dạng sữa hay nóng chảy là các giải pháp thay thế hiệu quả.

Thông tin sản phẩm

- PUR hot melt adhesive

- hot melt adhesive

- dispersion

- UF resin

PUR hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film | Open Time [min] / Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowatherm-Reaktant® 609.30 | PUR Hot Melt Adhesive | 15000 ± 3000 / 120 | 180 ± 60 / 120 | 3 ± 1 / 120 | 60 ± 5 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® 609.36 | PUR Hot Melt Adhesive | 13250 ± 3750 / 120 | 300 ± 60 / 120 | 5 ± 1 / 120 | 65 ± 5 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® 609.40 | PUR Hot Melt Adhesive | 7500 ± 1500 / 120 | 120 ± 60 / 120 | 2 ± 1 / 120 | 65 ± 5 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® 609.50 | PUR Hot Melt Adhesive | 25000 ± 5000 / 120 | 90 ± 30 / 120 | 1 ,5 ± 0,5 / 120 | 65 ± 5 | 1,1 ± 0,1 / 23 | de en fr |

| Jowatherm-Reaktant® MR 609.93 | Monomer-Reduced PUR Hot Melt Adhesive | 14000 ± 4000 | 180 ± 60 | 3 ± 1 | 65 ± 5 | 1,1 ± 0,1 / 20 | de en fr |

| Jowatherm-Reaktant® 609.00 | PUR Hot Melt Adhesive | 17000 ± 5000 / 120 | 240 ± 60 / 120 | 4 ± 1 / 120 | 60 ± 5 | 1,1 ± 0,1 / 20 | de en fr |

| Jowatherm-Reaktant® MR 609.90 | Monomer-Reduced PUR Hot Melt Adhesive | 30000 ± 10000 / 120 | 3 ± 1 / 120 | 65 ± 5 | de en fr |

hot melt adhesive

| Base | Viscosity [mPas] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film | Open Time [min] / Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowat-Toptherm® 236.50 | PO Hot Melt Adhesive | 8000 ± 2000 / 200 | 15 ± 2 / 190 / 120 | 110 ± 5 | 0,87 ± 0,02 / 20 | de en fr | |

| Jowatherm® 291.60 | EVA Hot Melt Adhesive | 5550 ± 1270 / 200 | 6 ± 2 / 180 / 120 | 80 ± 5 | 1,00 ± 0,02 / 20 | de en fr |

dispersion

| Base | Viscosity [mPas] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film | Open Time [min] / Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowacoll® 103.10 | PVAc Dispersion | 11000 ± 2000 / 20 | 6 ± 2 / RT | 1,08 ± 0,05 / 20 | de en fr | ||

| Jowacoll® 103.30 | PVAc Dispersion | 12500 ± 2500 / 20 | 9 ± 3 / RT | 1,08 ± 0,05 / 20 | de en fr | ||

| Jowacoll® 103.70 | PVAc Dispersion | 10000 / 20 | 5 - 7 / RT | 1,08 ± 0,05 / 20 | de en fr | ||

| Jowacoll® 124.00 | PVAc Glue for Flat Bonding | 9500 ± 1000 / 20 | 6 ± 1 / RT | 1,24 ± 0,05 / 20 | de en fr | ||

| Jowacoll® 124.79 | PVAc Glue | 19500 / 20 | 8 - 10 / RT | 1,24 ± 0,05 / 20 | de en fr | ||

| Jowacoll® ER 147.00 | Foil Adhesive | 10000 / RT | 0 – 3 | 1,35 ± 0,05 / RT | de en fr | ||

| Jowacoll® 148.00 | Foil Adhesive | 12000 ± 4000 / 20 | 0 – 3 | 1,35 ± 0,05 / RT | de en fr | ||

| Jowacoll® 148.20 | Foil Adhesive | 23000 / 20 | 0 – 3 | 1,35 ± 0,05 / RT | de en fr | ||

| Jowacoll® 148.70 | Foil Adhesive | 10000 / 20 | 0 - 4 | 1,25 ± 0,05 / RT | de en fr |

UF resin

| Base | Viscosity [mPas] / Temperature [°C] | Open Time [s] / Temperature [°C] / µm Film | Open Time [min] / Temperature [°C] | Softening Range (Kofler) [°C] | Density [g/cm³] / Temperature [°C] |

Download technical data sheet (PDF) | |

|---|---|---|---|---|---|---|---|

| Jowat® 950.20 | UF Resin | ca. 13 | de en fr | ||||

| Jowat® 950.50 | UF Resin | ca. 15 | de en fr |

Các sản phẩm được liệt kê chỉ đại diện cho một số lựa chọn hạn chế trong danh mục sản phẩm có sẵn. Tính sẵn có của sản phẩm có thể khác nhau tùy theo khu vực. Dữ liệu kỹ thuật, đặc điểm và lĩnh vực ứng dụng được cung cấp trong bảng phác thảo sự khác biệt giữa các chất kết dính khác nhau trong danh mục sản phẩm. Bộ phận Kỹ thuật Ứng dụng và Đại diện Kinh Doanh của chúng tôi luôn sẵn sàng tư vấn và hỗ trợ bạn tìm ra loại chất kết dính tốt nhất cho từng ứng dụng cụ thể.

Thông tin trong tài liệu này dựa trên kết quả thực nghiệm trong phòng thí nghiệm của chúng tôi cũng như kinh nghiệm thực tế trong lĩnh vực này, và hoàn toàn không tạo thành bất kỳ tính chất đảm bảo nào. Do có nhiều ứng dụng, vật liệu và phương pháp sử dụng khác nhau nằm ngoài tầm kiểm soát của chúng tôi, chúng tôi không thể chịu trách nhiệm pháp lý nào từ những chỉ dẫn này cũng như từ thông tin được cung cấp bởi dịch vụ tư vấn kỹ thuật miễn phí của chúng tôi. Các thử nghiệm của khách hàng trong các điều kiện hàng ngày, thử nghiệm về tính phù hợp ở các điều kiện vận hành thông thường và thử nghiệm phù hợp với mục đích là hoàn toàn cần thiết. Để biết thông số kỹ thuật cũng như thông tin chi tiết, vui lòng tham khảo bảng thông số kỹ thuật mới nhất.

Tin tức & Bài viết

Say hello to sand oak, concrete look and alpine white. These names refer to a small selection of numberless body colours that furniture store…

Jowat Manual with Tips and How To Guide - we help you finding the solution to your PUR cleaning problems

For many years, lacquering and decor foil lamination have been established finishing methods in the manufacture of wood-based materials for the…

The demand for environmentally compatible and harmless furnishings has constantly grown over the past years. Architects and interior fitters now have…

Like in any relationship, tensions are not desired when it comes to laminating surfaces. Tensions, i.e. mechanical stress, acting in and on the joint…

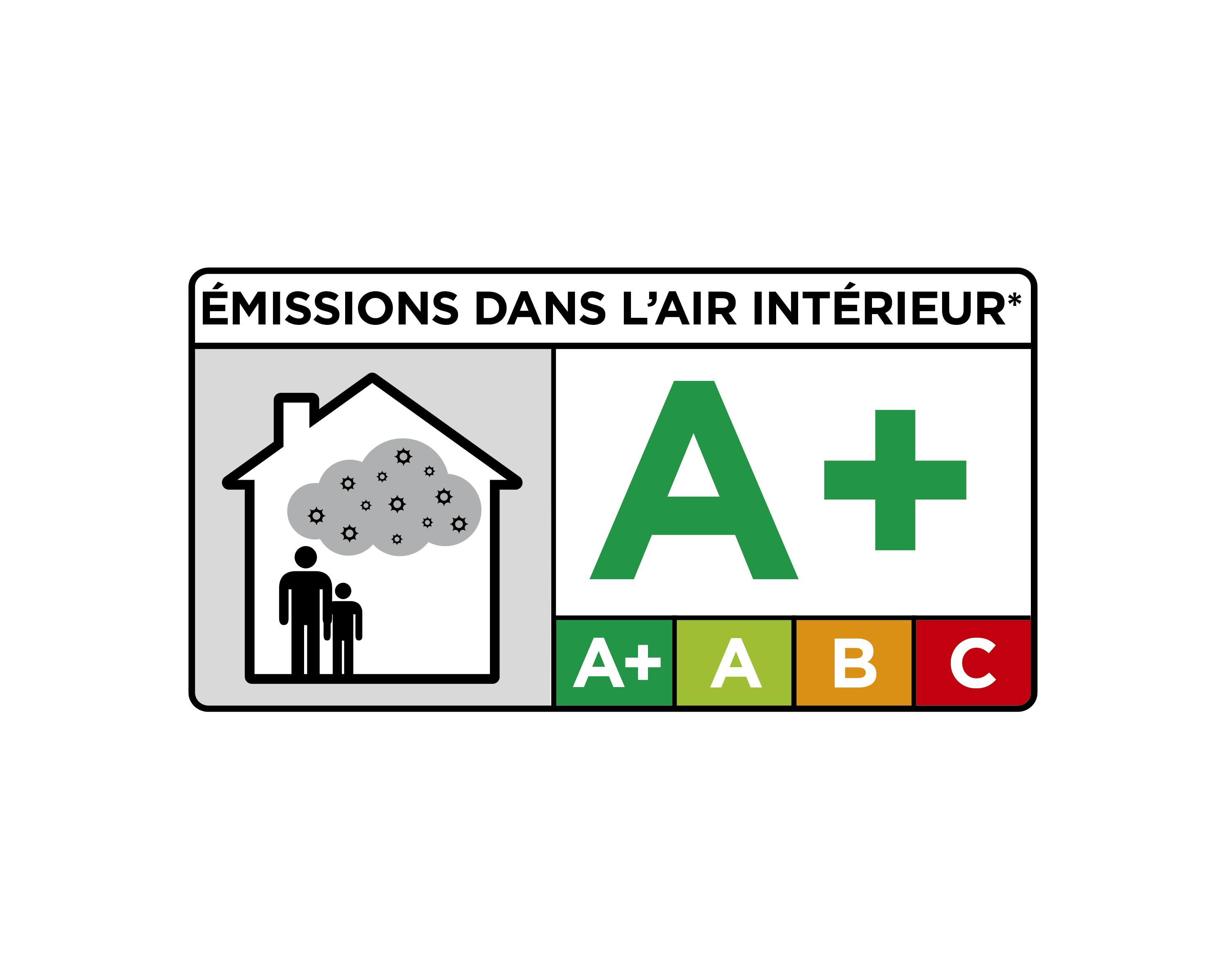

A new Jowat dispersion adhesive received the highest classification A+ from “Émissions dans l’air interieur,” currently the strictest rating system in…